|

UV News - Air & Water Articles | |

| Contact | Login | ||

| profile | uv systems | uv science facts | press releases | uv info | business programs |

UV News

|

|

|

UV News Note: These UV news items have been gleaned from the Internet. The UV news are partially reproduced as found. AAW takes no responsibility for their accuracy. The links to the full UV articles were active at the time of posting.

UV Articles 2009

![]() October 9, 2009:

STOP TB NEWS

October 9, 2009:

STOP TB NEWS

Stop TB Partnership Secretariat, World Health Organization

Stop TB Partnership highlighted at High-level Segment of UN Economic and

Social Council

The High-level Segment of the UN Economic and Social Council in Geneva in

July focused on improving global health. At a session called "Partnerships

in health–lessons from multi-stakeholder initiatives", Dr Marcos Espinal,

Executive Secretary of the Stop TB Partnership, addressed delegates about

the Stop TB Partnership's achievements and the challenges it faces...

The Stop TB Partnership, called the Stop TB Initiative at the time of its inception, was established in 1998. Its aim is to realize the goal of eliminating TB as a public health problem and, ultimately, to obtain a world free of TB. It comprises a network of international organizations, countries, donors from the public and private sectors, governmental and nongovernmental organizations and individuals that have expressed an interest in working together to achieve this goal. It is housed by the World Health Organization.

American Air & Water, Inc. is a Partner in Stop TB Partnership since

2007.

Visit the Stop TB Partnership website:

http://www.stoptb.org

![]() October 6, 2009:

New Orono Wastewater Facility Uses UV Light

October 6, 2009:

New Orono Wastewater Facility Uses UV Light

By Jessica Bloch, Bangor Daily News, Maine

...

Orono's Water Pollution Control Facility, which is now up and running, is a

state-of-the-art plant that Superintendent Paul Wintle feels will be a model

for other Maine communities.

"We'll be getting visitors, I'm sure, once the word gets around," said

Wintle, who led the Town Council's operations committee and Town Manager

Catherine Conlow on a tour Monday afternoon.

The facility cost about $15.2 million and took about 2 1/2 years to

complete. Olver Associates of Winterport was the environmental engineer for

the project.

The old facility had the capacity to process about 3.5 million gallons of

wastewater a day, Wintle said. The new plant can take on about 5.65 million

gallons. About 52 percent of the water handled there is from the University

of Maine campus, while the other 48 percent is town waste.

It's also better positioned for overflow during heavy rain, he added.

One of the landmark improvements has been the addition of a building in

which the wastewater is disinfected with ultraviolet light instead of the

standard chlorine bleach or other chemicals.

"It's a safer way of disinfecting," said Wintle, who is sure Orono's

facility is one of few in the state with the UV system.

"I think we're heads and shoulders above other communities of our size in

the state of Maine," Councilor Lianne Harris said.

![]() September

28, 2009:

Calgon Carbon to Provide Ultraviolet Disinfection System to Massachusetts

Water Resources Authority

September

28, 2009:

Calgon Carbon to Provide Ultraviolet Disinfection System to Massachusetts

Water Resources Authority

StreetInsider.com

Calgon Carbon Corporation has been selected by the Massachusetts Water

Resources Authority (MWRA) to provide an ultraviolet (UV) disinfection

system for the John Carroll Water Treatment Plant in Marlboro,

Massachusetts.

Twelve Sentinel Chevron 48 reactors (Chevron 48), scheduled to be delivered

in June 2012, will treat up to 450 million gallons of drinking water per

day. The Chevron 48, which is Calgon Carbon's highest flow unit in its

Sentinel product line, can treat up to 45 million gallons of water per day.

Earlier this year, the company was awarded a contract to supply 12 similar

reactors for the treatment of San Francisco's drinking water.

Commenting on this announcement, Jim Sullivan, Calgon Carbon's vice

president of UV technologies and business development said, "We are pleased

that the MWRA selected our Sentinel® design to meet Boston's disinfection

and compliance needs. The continued success of the Chevron 48 strengthens

our position in the growing, global drinking water disinfection market."

![]() September

7, 2009:

Wisconsin School District Uses UV Light to Fight H1N1

September

7, 2009:

Wisconsin School District Uses UV Light to Fight H1N1

Kstp.com/news by Becky Nahm

A school district in Wisconsin is utilizing light in its fight to prevent

the spread of the H1N1 virus and other contagious illnesses.

The Mequon-Thiensville School District, located near Milwaukee, owns a

mobile UV sanitizer.

The machine uses ultraviolet light to scan classrooms and zap flu germs

before they spread.

The district bought the UV sanitizer a couple of years ago and found it

worked well when H1N1 hit last spring.

The district superintendent, Dr. Demond Means, said, "We were able to really

focus attention on sanitizing classrooms quickly and efficiently with the

device."

The machine only takes about 12 minutes to clean and sanitize a room. It

costs about $3,000.

![]() August 19, 2009:

Aquionics to unveil new UV systems at WEFTEC

August 19, 2009:

Aquionics to unveil new UV systems at WEFTEC

WaterandWasteWater.com / By Damian Corbet / Source: Aquionics, Inc. - Halma

Group

Aquionics to unveil new UV systems

Erlanger, KY -- UV disinfection specialist Aquionics will be unveiling

two new product ranges at this year's WEFTEC Technical Exhibition &

Conference in Orlando, Florida (booth # 3821). The first is its new OpenLine

range of open channel UV treatment systems for the secondary wastewater

market, employing a new type of low pressure high output (LPHO) amalgam

lamps. The second is a new range of USEPA validated closed vessels, known as

the AF-3 Series, also employing LPHO lamps. In addition, the company will be

showing its validated, closed vessel medium pressure InLine+ UV system.

The OpenLine Series has been designed to treat secondary wastewater flows

over a wide range of flows and UV transmittances. Employing a new type of

LPHO amalgam lamp that possesses a more stable output over its operating

life, the OpenLine Series offers a neatly packaged solution that is

pre-engineered for wastewater applications.

The AF-3 Series also employs high efficiency LPHO amalgam lamps, the largest

of which has a maximum output of 500W, one of the largest ever deployed in a

UV system. By employing CFD models at the start of the design process, the

AF-3 Series is able to utilize the full benefit of the lamp output,

resulting in a high flow per kW system efficiency. Validation work in

accordance with the USEPA UV Disinfection Guidance Manual (UVDGM) has been

completed.

The two new products compliment the highly successful InLine+ Series, which

is specially optimized to treat high volume drinking water, reuse and

wastewater flows and is validated in accordance with all major guidelines,

including the USEPA UVDGM, the AwwaRF/NWRI and the German DVGW standard for

drinking water.

“It’s exciting to see our product portfolio broaden,” says Aquionics

President, Bill Decker. “In launching these two new product lines we are

able to offer our customers a full portfolio of solutions to meet their

disinfection needs.”

A selection of Aquionics' other UV systems will also be on display,

including a transparent model showing the internal workings of a UV system,

such as the lamp wiper mechanism. Experts will be on hand at all times to

provide technical expertise and answer questions.

WEFTEC - 82nd Annual Water Environment Federation Technical Exhibition and

Conference, October 10-14, 2009

![]() August 13, 2009:

World’s first medium pressure, closed vessel UV systems to gain formal

approval for wastewater reuse

August 13, 2009:

World’s first medium pressure, closed vessel UV systems to gain formal

approval for wastewater reuse

Environmental-expert.com / Source: Aquionics, Inc. - Halma Group

Berson's InLine+ medium pressure, closed vessel UV systems - validated for wastewater reuse applications

Berson's InLine+ medium pressure, closed vessel UV systems are the first

in the world to gain formal approval for wastewater reuse applications.

Having undergone extensive third party testing by Carollo Engineers in the

USA, they have been formally approved for post-filtration and reverse

osmosis applications by the California Department of Public Health (Title-22

validation) and are now validated for wastewater reuse applications in

accordance with AwwaRF/NWRI* guidelines. Berson's UV systems are sold in

North America by its sister company Aquionics Inc.

Wastewater reuse has been practiced in various forms for decades, with the

USA leading the way in reuse research. It is now a major issue worldwide,

with large areas of western and southern USA experiencing chronic water

shortages. Large-scale reuse projects are now also being considered in other

water-poor regions of the world such as Australia, Singapore, China and

southern Europe.

The most common method of wastewater disinfection for reuse has long been

chlorination. Despite chlorine’s impressive track record, concerns regarding

disinfection by-products (DBPs) and, more recently, disinfection performance

with respect to pathogen inactivation, are driving the conversion from

chlorine disinfection to other disinfection methods such as UV, which does

not produce any significant DBPs.

Closed vessel UV systems are easy to install within existing pipework, so

there is minimal disruption to plant operation. Day to day operation is

simple and maintenance is minor. The only regular requirement is changing

the UV lamps and wiper rings once a year, a straightforward operation that

can be carried out by on-site personnel.

Potential applications for wastewater reuse are extremely wide-ranging and

include any instance where water is needed for non-potable use. The most

popular and widespread use is for agricultural irrigation and for other

irrigation applications such as golf courses, parks, fountains and lawns.

Reclaimed wastewater is also used for groundwater recharge applications such

as aquifer storage and recovery or preventing saltwater intrusion in coastal

aquifers. Other uses include toilet and urinal flushing, fire fighting,

foundation stabilization in the construction industry and artificial snow

generation. In all these applications, reused wastewater relieves the burden

on existing potable supplies.

“We are extremely pleased that we have achieved this important validation,'

commented Berson's Managing Director Andrew Clark. 'Our state-of-the-art

technology uses UV sensors to actually measure how the UV systems are

performing. This permits much greater control while saving energy,

especially when compared to the existing methods of applying crude safety

factors to systems that use high numbers of lamps or are unwiped.”

![]() August 13, 2009:

UV disinfection systems receive additional validation

August 13, 2009:

UV disinfection systems receive additional validation

Fluidhandling.com.au

THE Berson InLine+ series of UV water disinfection systems is now fully

validated in accordance with the USEPA UV Disinfection Guidance Manual (UVDGM).

Berson says that the validation certifies the use of the systems for the

Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) released by EPA

in November 2006, and their products are no longer subject to any

Cryptosporidium or Giardia patent fees for UV disinfection applications

worldwide.

The testing was conducted by Carollo Engineers at its Portland, Oregon

validation facility in the USA and covered a three-dimensional matrix of UV

transmittance, flow and reduction equivalent dose, using both T1 and MS-2

phage test surrogates. Dose delivery equations were derived for all reactors

that predict T1 and MS-2 RED as a function of flow, UV-T, UV sensor

readings, and microbe UV sensitivity.

Berson says it is only one of a few UV system suppliers capable of providing

a complete range of UV systems with capacities between 10 – 10,000 m³/hour,

certified to the newest DVGW (German Technical and Scientific Association

for Gas and Water) norm, W294, Part 1, 2 & 3 – the highest standard

currently possible in the world.

![]() August 11, 2009:

UV treatment of choice for Maine’s twin cities

August 11, 2009:

UV treatment of choice for Maine’s twin cities

WaterTechOnline.com

AUBURN, ME — The Auburn Water District is using stimulus funds to help

finance its new $7.7 million ultraviolet (UV) water treatment plant being

built on the banks of Lake Auburn, an August 10 Sun Journal story said.

Local, state and national officials were scheduled to take part in a

ceremonial groundbreaking on August 11 at the construction site.

John Storer of the Auburn Water District said that using UV disinfection

treatment appealed to the district because “it’s not another chemical we’re

putting into the water.”

Construction, which already has started, is scheduled to wrap up in 2010.

The facility will provide treated water to the cities of Auburn and

Lewiston, the story said.

![]() July 29, 2009:

New UVCalc Module for UV light disinfection

July 29, 2009:

New UVCalc Module for UV light disinfection

Water and Wastewater.com

Charlottesville, VA -- Blue Ridge Numerics, Inc. today announced the

availability of the new CFdesign UVCalc Module, an industry-first Upfront

CFD solution for simulating and validating ultraviolet (UV) reactor

performance to ensure accurate fluence rates (irradiances) for UV light

disinfection. The use of germicidal UV light is a rapidly expanding

technology that is used to ensure public safety by deactivating the DNA of

bacteria, viruses, and other pathogens, removing their ability to multiply

and cause disease.

With the new partnership of Blue Ridge Numerics, Inc. and Bolton

Photosciences, Inc., design engineers developing UV applications for

drinking water disinfection, wastewater treatment, and manufacturing

processes for the food and beverage, medical device, pharmaceutical, and

semiconductors industries (among others), can now easily leverage fluid flow

and UV calculation capabilities to speed up and optimize their product

development process.

The CFdesign UVCalc Module furthers the commitment of Blue Ridge Numerics to

empower engineers with CAD-driven simulation tools that optimize product

performance during the digital design phase. The ability to validate UV

reactor performance for biodosimetry testing, while still on the digital

drawing board, is the focus of CFdesign and the UVCalc Module. Exploration

of multiple design scenarios before building prototypes for physical testing

equates to significant cost and time savings.

The Synergy of CFdesign and UVCalc

For many years, CFdesign, the leading design tool for Upfront CFD, has

successfully been used to simulate the hydraulic performance through UV

reactors. To build on existing capabilities and address the current needs of

its customers, Blue Ridge Numerics realized the importance of a reliable

solution for predicting UV fluence rates in CFdesign.

The knowledge and experience needed came from a new partnership with Dr. Jim

Bolton, a recognized expert in the UV calculation field and developer of

UVCalc, a trusted and tested UV calculation tool currently in its 3rd

generation.

“As the use of UV light disinfection rapidly expands around the world,

especially in emerging countries like China and India where infrastructure

is aggressively being developed to support population demands, companies

will be looking for cost effective solutions to help more accurately design

their products,” said Ed Williams, CEO, Blue Ridge Numerics.

“Together CFdesign and UVCalc provide a holistic and accessible solution to

help design engineers in water treatment and manufacturing industries more

easily simulate and predict accurate reactor performance.”

How Does the CFdesign UVCalc Module Work?

Histogram shows the distribution of UV Dose using 200 flow partical traces

UVCalc, developed by Dr. Bolton, is a software program that allows an

engineer to map out the fluence rate or irradiance distribution in a UV

reactor. The combination of CFdesign and UVCalc together in the CFdesign

UVCalc Module allows engineers to simulate the UV fluence rate in

combination with the flow field, to ultimately predict the fluence or UV

dose delivered.

Predicting the UV dose is vital, but even more important is studying and

understanding the sensitivity of a reactor design with respect to changing

conditions, such as piping connections, water transmittance, and flow rate.

“Validating a UV reactor’s performance for biodosimetry testing through

digital “what if” scenarios helps significantly reduce the number of

physical prototypes that a company needs to build and ensures a more

accurate design upfront in the process,” said Dr. Jim Bolton, President,

Bolton Photosciences, Inc. “CFdesign provides an easy to use software

platform that addresses geometry and flow calculations at the design

engineering level. The combination of UVCalc and CFdesign creates a

synergistic design tool that provides the data and visualization needed to

quickly determine the optimum UV reactor performance.”

![]() July 27, 2009:

French WWTP installs LIT open channel UV-system

July 27, 2009:

French WWTP installs LIT open channel UV-system

EnvironmentalExpert.com

Recently O.E.I. France, distributor of LIT for the French market,

installed a LIT open channel UV system in the South of France close to the

Mediterranean Sea. The system is placed in the municipal Waste Water

Treatment Plant (WWTP) of the village of Canet-en-Roussillon with 10,182

inhabitants. The capacity of the WWTP however is based on the summer season

population of 66,000 inhabitants.

The LIT UV system is part of a classical urban WWTP water line. The design

of the plant was based on an hourly peak flow of 21,000 m³ per day and

treats on average 12,250 m³ per day. The municipal waste water is first

treated by an activated sludge system including a clarifying process. Just

before the discharge into the Têt River the effluent passes through the

UV-system. The river then runs for 2 more kilometers before it reaches and

flows into the Mediterranean Sea.

The installed LIT UV system consists out of 2 banks of 3 modules with twelve

350W lamps each. The lamps are submerged and placed parallel to the flow.

The entire UV system is installed outdoor. All electrical cabinets are built

in stainless steel, to withstand the Mediterranean climate conditions.

Because in summer the outside temperature can reach up to 40°C, the cabinets

are equipped with air conditioners. An Automatic Water Level Control System

(AWLCS) including a channel slide gate assures a constant water level in the

UV channel. Integrated monitoring and control of the water level is

essential for the performance of horizontal open channel UV systems. The

UV-sensor controls continuously the applied UV intensity. An Ethernet

connection with Scada system facilitates remote logging and control of the

entire UV system.

The installation of the LIT UV system in Canet-en-Roussillon assures the

water quality to comply with the stringent European Bathing water directive.

This compliance is an essential part of the annual review by the Foundation

for Environmental Education (FEE) and allows this popular touristic area to

wave the blue flag on their beaches. The blue flag is an indication for

sustainable development at beaches/marinas through strict criteria dealing

with water quality, environmental education and information, environmental

management, and safety and other services.

![]() July 20, 2009: Gray Water Recycling Systems 2009 "SEED" Award Winner for

Water Conservation

July 20, 2009: Gray Water Recycling Systems 2009 "SEED" Award Winner for

Water Conservation

ReuseGrayWater.com

Gray Water Filter Array and UV Disinfection System

The South Bay Business Environmental Coalition (SBBEC) has awarded their

2009 SEED Award for Water Conservation to Gray Water Recycling Systems, LLC.

The SEED Awards, SoCal Environmental Excellence Development, are given to

Southern California businesses that have exhibited excellence in helping

improve environmental sustainability and quality of life in the greater

South Bay Area of Los Angeles.

Gray Water Recycling Systems was selected for extraordinary work in the area

of Water Conservation and their significant and notable efforts to help

reduce environmental footprints.

Ed Begley, Jr., spokesperson for Gray Water Recycling Systems, accomplished

actor, avid long time environmentalist and star of the hit TV series Living

With Ed stated, "This is the first of many awards for GWRS. The systems

technology and operation is fantastic, it will have a huge impact on water

conservation. I applaud the SBBEC for their foresight in the recognition of

this urgently needed product."

The SBBEC is comprised of representatives from the private and public

sectors of the South Bay area of Los Angeles County who sought a forum in

1991 to express common concerns for environmental issues and regulations

impacting businesses and communities.

Gray Water Recycling Systems, LLC manufacturers gray water purification and

disinfection systems for single and multi family homes, resorts, hotels and

commercial use. Units capture water from shower, bath and laundry, then

purify, disinfect, store and deliver that water to be safely reused for

irrigation and other recycled water uses.

Full text: Gray

Water Recycling Systems 2009 "SEED" Award Winner for Water Conservation

![]() July 17, 2009:

Aquatic Centre goes UV

July 17, 2009:

Aquatic Centre goes UV

Coastreporter.net by Brent Richter

Sechelt – The lap pool at the Sechelt Aquatic Centre will soon have some

ultra-cool technology to keep the pool ultra-clean without the current salty

taste.

The Sunshine Coast Regional District (SCRD) announced Tuesday, July 14 that

it would be installing an ultraviolet (UV) light disinfecting system this

fall.

The new system, which is currently used in the leisure pool and hot tub,

works by killing bacteria and viruses that live in the water and is

extremely effective when combined with small amounts of chlorine, according

the SCRD.

Bruce Bauman, area recreation manager for the SCRD, said there was several

reasons for switching to UV from the salt system currently used for the lap

pool, but its affordability and maintenance hassles with the salt system

were key.

“The commercial salt system parts are becoming increasingly difficult to get

a hold of and as a matter of fact, in some cases, are impossible to find,”

he said.

Bauman said the SCRD is still finalizing the cost of installing the UV

system, but the operating costs would be substantially lower. The SCRD has

also applied for grant funding from the federal government that would cover

one third of the total cost. The grant application is in the approval

process now.

Public pools in B.C. must maintain a level of chlorine as disinfectant in

the water, but the UV system will give the pool a fresh water feel to it,

Bauman said.

“The UV system will allow us to keep the chlorine levels at an absolute

minimum. It’s the same system that’s presently used in many drinking water

systems,” he said.

The system is set to be installed during the annual two-week maintenance

shut down of the pool from Aug. 22 to Sept. 7 and when it reopens, the pool

will lose its distinctive salty taste.

“Really the only experience that [people] are going to find different is

that the pool is not going to taste like the Georgia Strait,” Bauman said.

![]() July 13, 2009:

CA community turns to UV for wastewater disinfection

July 13, 2009:

CA community turns to UV for wastewater disinfection

WaterTechOnline.com

AUBURN, CA — To meet regional water quality standards, the Auburn

wastewater treatment plant is getting an upgrade that includes the

installation of an ultraviolet disinfection system, a July 13 AuburnJournal

story reported.

The new system will replace the plant’s current chlorine disinfection

system, used to treat the water before it drains into a creek near Ophir.

According to Bernie Schroeder of the local public works agency, the

community is getting a deal on the system. It was originally priced at $10

million, but due to the struggling construction climate, the system’s price

has dropped by $2 million.

Schroeder said residents can expect that their monthly sewer rate, which is

about $55, will stay the same, the story said. Construction is expected to

begin in September.

![]() July 10, 2009:

Cutting pool chlorine

July 10, 2009:

Cutting pool chlorine

TheStar.co.uk

A MODERN cleaning system has been brought in to cut the amount of

chlorine in the pool at the Doncaster Dome leisure centre. Managers say the

ultraviolet cleaner will make the pool one of the cleanest in the country.

It cleans almost a million litres of water every 90 minutes meaning the

amount of chlorine needed is halved - making the pool more accessible for

people who suffer from allergies and skin conditions resulting from exposure

to chlorine and similar chemicals found in swimming pools.

The new system is more energy efficient. Terry Parker, head of facilities at

The Dome, said: "The new UV system is already proving to be a success. We

are using less chlorine now and so the Lagoons smell much fresher, and that

has been noticed by both staff and customers. It also means the water is

even more accessible to children and adults who may suffer from skin

conditions."

The £32,000 unit is the latest improvement made at The Dome this year.

![]() July 8, 2009:

Anglian Water choose UV as solution to Cryptosporidium

July 8, 2009:

Anglian Water choose UV as solution to Cryptosporidium

Approvedbusiness.co.uk

atg UV disinfection system - effective against Cryptosporidium

In June 2008, a rabbit got into the wash water tank at the Pitsford

Drinking Water Plant of Anglian Water, leading to contamination of the

treatment works with Cryptosporidum, a chlorine resistant parasitic

micro-organism.

The parasite was detected on June 24 and, following consultation with health

and local authorities, a notice to boil drinking water was issued for more

than 100,000 households and 250,000 people served by the plant. About

500,000 litres of bottled water were also distributed.

A decision to install UV led to seven systems – including two validated UV

systems from atg UV Technology – being installed by the end of the weekend

following the initial discovery. A week later, all water being produced was

free from Cryptosporidium.

The UV systems are automatically wiped and lamp output is monitored using a

specifically designed UV monitor camera. The power of the UV lamp is

adjusted automatically to ensure the correct UV dose is delivered to the

water. The units are capable of being controlled locally or remotely by

SCADA. The system adjusts automatically for lamp ageing and changes in the

transmittance of the water to deliver a constant UV dose.

The units were installed in line into a 24-inch main. The design avoids

bends that would be detrimental to system performance. Lamps can be changed

online and the automatic wipers maintain the optical path, ensuring optimum

performance, protecting Anglian Water from future Cryptosporidium outbreaks.

![]() June 24, 2009:

Aquionics InLine+ Closed Vessel UV Disinfection Systems Get UVDGM Validation

For Drinking Water Use

June 24, 2009:

Aquionics InLine+ Closed Vessel UV Disinfection Systems Get UVDGM Validation

For Drinking Water Use

Wateronline.com

Aquionics' InLine+ medium pressure ultraviolet system

Aquionics' InLine+ series of UV water disinfection systems are now fully

validated in accordance with the USEPA UV Disinfection Guidance Manual (UVDGM).

The validation certifies the use of the systems for the Long Term 2 Enhanced

Surface Water Treatment Rule (LT2ESWTR) released by EPA in November 2006.

The testing was conducted by Carollo Engineers at its Portland, Oregon

validation facility and covered a three-dimensional matrix of UV

transmittance, flow and reduction equivalent dose, using both T1 and MS-2

phage test surrogates. Dose delivery equations were derived for all reactors

that predict T1 and MS-2 RED as a function of flow, UV-T, UV sensor

readings, and microbe UV sensitivity.

"We are delighted to have achieved this important validation as it confirms

our position at the forefront of UV disinfection technology," comments

Aquionics President Bill Decker. "From the time we supplied some of the very

first UV drinking water disinfection units in the USA in 1987, we have been

actively involved in providing communities with safe, reliable UV

disinfection for drinking water and this latest validation continues our

long tradition of investing in the industry. We are proud to be able to

offer communities the choice of using our state-of-the-art UV disinfection

systems, knowing that they meet the very latest and most stringent drinking

water standards. I would also like to add that Aquionics products are no

longer subject to any Cryptosporidium or Giardia Patent fees for UV

disinfection applications worldwide."

Aquionics is part of the Fluid Technology Division of Halma p.l.c. (www.halma.com).

Along with fellow Halma companies Hanovia Limited in the United Kingdom and

Berson UV-techniek in the Netherlands, Aquionics is the world leader in

closed vessel UV technology for progressive, non-chemical disinfection and

microbiological control. The company's UV systems are used in a wide variety

of applications including municipal water and wastewater treatment, high

purity water treatment in the pharmaceutical, electronics and power

generation industries, and also food and beverage processing, brewing,

winemaking and aquaculture.

![]() June 24, 2009:

Safety retrofit nearly complete for Cupertino civic center fountain

June 24, 2009:

Safety retrofit nearly complete for Cupertino civic center fountain

MercuryNews.com by Matt Wilson

The dormant civic center fountains outside Cupertino Community Hall and

library could be splashing again in late July.

Installation of an ultraviolet lighting system to ward off potential

parasites is scheduled to wrap up next month, according city officials.

The fountains have been mostly inactive since early 2008, after the Santa

Clara County Public Health Department tested them for presence of a parasite

called cryptosporidium that effects the intestinal tract and shut down the

water display as a precautionary measure. The parasite is common in

interactive water fountains.

While there was no evidence of the parasite, county officials concluded that

all fountains that allow direct human and animal contact must be modified to

treat the water with ultraviolet light to kill any potential parasites.

In December, the city council awarded a contract to Pacific Water Art Inc.

to retrofit the fountains with the ultraviolet system. Ralph Qualls,

director of public works, said that work is wrapping up on the fountains

with the goal of turning the water back on sometime in late July.

City staff declined to elaborate further until the city council in July

reviews a staff report on the progress and prognosis of the fountain

retrofit and how it correlates with county regulations.

The rows of fountains, which shoot jets of water up a few feet from the

ground, are a popular play area for children on hot summer days and after

visits to the library.

According to the Centers for Disease Control, cryptosporidiosis is a

diarrheal disease that can cause severe intestinal tract distress.

The parasite is protected by a hard outer shell that allows it to survive

outside the body for extended periods. The disease is usually spread through

ingesting recreational water tainted with feces, usually from animals or

children's diapers. The hard outer shell makes the parasite resistant to

typical chlorine treatment, thus the need for the UV treatment system.

![]() June 3, 2009:

BIO-UV to equip city of Geneva

June 3, 2009:

BIO-UV to equip city of Geneva

Eurospapoolnews.com

A BIO-UV installation - medium pressure ultraviolet system

Following an assessment, BIO-UV has been selected to provide all public swimming pools (a total of 7 establishments) managed by Geneva in Switzerland with equipment containing medium-pressure lamps.

Benoît Gilmann, CEO of BIO-UV, said: “We are delighted to have been chosen by the city of Geneva. With over 1,000 pools already equipped in Europe, of which 500 are in France, dechloramination by UV light is by far the most commonly used technique and is also to the complete satisfaction of the swimmers, staff and management of these establishments.”

The scientific research over the last 5 years, the French and international

publications and the analysis campaign initiated by the French Ministry of

Health and the DASS have all shown that, when using UV lamps,

medium-pressure lamps have the most conclusive results on the reduction of

trichloramines. These latter are a component of combined chlorine and one of

the most harmful by-products to the health of swimmers and staff as well as

a source of numerous public health problems.

Furthermore, it is now well recognised and proven that, when properly

installed, UV lamps do not generate any additional by-products such as THM,

and this includes medium-pressure lamps.

![]() June 1, 2009: Advanced

Biotechnologies, Inc. (ABI) Adds UV-Inactivated Purified Whole Virus Product

to Aid in Research of Human Influenza

June 1, 2009: Advanced

Biotechnologies, Inc. (ABI) Adds UV-Inactivated Purified Whole Virus Product

to Aid in Research of Human Influenza

PR.com

ABI adds (H2N2) Purified Whole Virus, UV-Inactivated for use in H2N2

subtype-specific protein-based testing. Catalog # 10-126-000

Columbia, MD --(PR.com)-- Human Influenza A/2/Japan/305/57 (H2N2) Purified

Whole Virus, UV-Inactivated was completely inactivated by ultraviolet light

irradiation. The inactivation was validated by cell culture based assay and

had no effect on the hemagglutinin titer by hemagglutination assay (HA) and

retained viral morphology by TEM. The inactivated, purified human influenza

A virus will be useful for any H2N2 subtype-specific protein-based testing.

Catalog # 10-276-000

Advanced Biotechnologies Inc. (ABI) www.abionline.com is a privately held

biotechnology company specializing in the development, manufacture, and

supply of critical products and services for the research and monitoring of

infectious disease. ABI has been a integral partner for over 27 years to

various Pharmaceutical, Laboratories, Diagnostic, and Research companies by

using unparalleled manufacturing techniques to produce

large-scale in vitro virology products and services.

For more information on other inactivated

Influenza A virus subtypes (H1N1, H3N2)

Contact Alicia Heazlitt

phone: 800-426-0764

![]() May 24, 2009: Plan

to clean water with UV light wins business plan competition

May 24, 2009: Plan

to clean water with UV light wins business plan competition

DailyDemocrat.com

A plan for cleaning wastewater with ultraviolet light won the $15,000

first prize in the annual Big Bang! Business Plan Competition at the UC

Davis.

The funding will help the students complete a prototype of the novel

technology, which will be tested first at UCD' wastewater treatment

facility. The system has the potential to replace chlorine as a disinfectant

in swimming pools and hot tubs.

"This was the toughest deliberation in the history of this competition,"

said Roger Akers, a Sacramento venture capitalist who estimates that he has

evaluated some 10,000 business plans in his 30-year career. Akers was one of

seven volunteer judges who determined the top Big Bang! winners.

The Big Bang! competition, founded in 2000 by students at the UCD Graduate

School of Management, has become one of the best-known business plan

competitions on the West Coast.

Akers Capital and DFJ Frontier were among the 16 Northern California venture

capital firms, law practices and major firms that provided the prize money,

coaching and volunteer judges for this year's Big Bang!

MBA students run the competition without any financial support from the

university. This year's student co-chairs were Julia Barg and Adelina Ratner.

UltraV, the winning business concept, relies on technology developed by

Bassam Younis, a professor of civil and environmental engineering at UCD. To

bring his technology to market, Younis relied on the UCD Energy Efficiency

Center to connect him with students in engineering and management. Those

connections led to UltraV.

Elisabetta Lambertini, a Ph.D. student in engineering with a background in

business, is chief technology officer of the incipient startup. MBA

candidates Mananya Chansanchai, Yong Kim and James Bui are vice president of

development, chief financial officer and vice president of sales and

marketing, respectively.

According to Chansanchai, 75 percent of wastewater treatment plants around

the country still disinfect water with chlorine, a toxic chemical that is

dangerous to transport and store. The other 25 percent have adopted UV

disinfection systems, but these systems use mercury lamps in direct contact

with water. Because of their toxicity, mercury lamps are expensive to

dispose of. Direct contact with water is another drawback, because the lamps

become covered with algae and require frequent cleaning.

Younis' design uses xenon lamps that do not come into contact with water.

Instead, the lamps pulse UV light at water as it circulates through an

enclosed cylinder.

UltraV has an agreement to test the technology at the UCD wastewater

treatment facility, which currently uses a mercury lamp UV disinfection

system. The test will allow direct comparisons of the xenon and mercury

systems.

The students applied for a $150,000 grant from the California Energy

Commission to complete a prototype for the campus test. They also filed an

application for a patent.

"This is an amazing opportunity," Chansanchai said after her team won the

$15,000 Big Bang! prize. "We think we have a product that will make the

world cleaner and healthier for our children."

![]() May 14, 2009:

Construction begins on high tech water plant

May 14, 2009:

Construction begins on high tech water plant

San Francisco Examiner

By: Juliana Bunim

Mayor Gavin Newsom broke ground Thursday on what will be the largest

ultraviolet water treatment plant in California. Using state-of-the-art UV

disinfection technology, the $112 million Tesla Treatment Facility will

treat water from the Hetch Hetchy system. It will also create hundreds of

thousands of jobs for building and construction workers in San Joaquin and

Stanislaus counties.

“Today we break ground on more than just an innovative major new water

treatment plant,” said Mayor Newsom. “Today we begin a new partnership

between the San Francisco Bay Area and the San Joaquin Valley that will

bring the latest technologies to protect our water supplies and create

thousands of good jobs in San Joaquin and Stanislaus Counties at a time when

they’re urgently needed.”

The new facility is slated for completion in 2011.

The plant is one of 85 projects within the San Francisco Public Utilities

Commission’s Water System Improvement Program to repair, replace and

retrofit aging pipelines, tunnels, reservoirs and other water-delivery

facilities. Overall, these projects will generate about 28,000 jobs

throughout the greater Bay Area and the Central Valley in the next five

years.

![]() May 5, 2009:

Crystal IS and Sanan Optoelectronics Announce Joint Development of

Commercial UV-C LEDs

May 5, 2009:

Crystal IS and Sanan Optoelectronics Announce Joint Development of

Commercial UV-C LEDs

BusinessWire.com

GREEN ISLAND, NY - Crystal IS, Inc., the world’s leading developer of

ultraviolet light emitting diodes (UV-C LEDs) and Sanan Optoelectronics Co.

Ltd., the largest manufacturer of full color LEDs in the People’s Republic

of China, today announced they had signed a memorandum of understanding (MOU).

The MOU defines a joint development program, whose goal is to establish

pilot manufacturing of LEDs operating in the UV-C part of the

electromagnetic spectrum. During the term of this MOU, both parties intend

to negotiate a long term business agreement covering high volume

manufacturing, marketing and sales.

“Working with an experienced and dynamic company like Sanan Optoelectronics

will significantly speed up the market introduction of UV-C LEDs,” said

Crystal IS CEO Steven Berger. “Leveraging Sanan Optoelectonrics’ unique

expertise in processing and packaging will allow us to focus on making the

precision substrates required for efficient UV-C LEDs”

“The opportunity to partner with Crystal IS on a new LED technology will

help Sanan Optoelectronics maintain its leadership position for the future,”

said Sanan Optoelectronics CEO Simon Lin. “We expect downstream integrators

of UV-based products will welcome an established supply train for this new

product.

The developed UV-C LEDs will operate at the optimal germicidal wavelength,

and are ideal for use in water and air sterilization products. Initial

applications will include portable and residential point-of-use systems such

as cleantech alternatives to bottled water and in-home counter-top systems.

The technology roadmap also includes industrial and municipal applications,

where long-lasting, energy-efficient LEDs are ideal replacements for

existing mercury-based light sources.

![]() April 21, 2009:

Degrémont Technologies-Ozonia supply UV reactors to drinking water plants

April 21, 2009:

Degrémont Technologies-Ozonia supply UV reactors to drinking water plants

Filtration + Separation filtsep.com

Degrémont Technologies-Ozonia have supplied AQUARAY® UV reactors to

two drinking water plants in Paris - the largest drinking water UV contract

in Europe

Degrémont Technologies-Ozonia will equip the ozone drinking water treatment

plants in Joinville and Orly, Paris with AQUARAY® H20 UV reactors, bringing

them to full compliance with new regulations on pathogens and bromate

restrictions and with a capacity to treat 2 x 300 000 m³/day of drinking

water.

The UV reactors will act as a barrier in the disinfection process against

pathogenic microorganisms like viruses, bacteria and parasites, and are

particularly effective for chlorine-resistant microorganisms such as

Cryptosporidium and Giardia, even at low doses.

The AQUARAY® H20 UV water disinfection reactors (20" Mono and 20" Duplex)

are certified by the German Technical and Scientific Association for Gas and

Water (DVGW) and the US Environmental Protection Agency (EPA), and guarantee

consistent compliance with the prescribed amount of 40mJ/cm² defined in

conjunction with the Paris Water Management company. UV treatment solutions

must also be approved by the French Ministry of Health when used in France

to prevent parasitic risks. Currently, Degrémont Technologies-Ozonia is the

only manufacturer to have obtained this approval.

![]() April 16, 2009: S. Oregon pool to go

chlorine-free

April 16, 2009: S. Oregon pool to go

chlorine-free

KDRV.com by Tove Tupper

MEDFORD, Ore. - A Southern Oregon pool is the first in the area to

install a new UV water purification system.

The Rogue Valley Family YMCA pool will no longer use chlorine.

"Chlorine is good, salin is better, and UV is best," says Rogue Valley

Family YMCA Facility Director Robert Horton.

With the new system, water passes through a 2,500 UV watt light, designed to

kill 99.9 percent of all germs, bacteria, and living organisms. It will stop

itchy eyes and skin, and swimmers won't even need goggles.

Though the system cost $35,000 to install, the YMCA says it will save money

in the long run.

"We can now save on day-to-day basic money, because we're not having to

spend so much on chlorine and other chemicals," says Rogue Valley Family

YMCA Executive Director Brad Russell.

It is also more environmentally friendly, and the UV treated water will help

keep bathing suits last longer.

The World Health Organization says this water is almost clean enough to

drink.

![]() March 30, 2009:

Council awards bid for UV filter

March 30, 2009:

Council awards bid for UV filter

BandonWesternWorld.com

The Bandon City Council has awarded a bid for providing an ultraviolet

disinfection system for the city’s wastewater treatment plant.

At the council’s March meeting, the bid was awarded to Spectral Innovations

Ltd., in the amount of $183,105.

The project involves upgrading the disinfection system at the wastewater

treatment plant to comply with the Department of Environmental Quality

discharge permit requirements, according to City Manager Matt Winkel.

In June 2007, the city entered into a Mutual Agreement and Order with DEQ,

under which the city was to install the UV system by May 2009. The city bid

the equipment purchase and received two bids, and awarded the bid to UV

Doctor Systems LLC, the low bidder. However, after six months the company

could not provide the required bonding, so its bid was rejected, Winkel

explained.

The city subsequently re-bid the equipment, and received two bids from

Siemens and Aquaionics. However, both bids were determined to be

non-responsive, since the city’s existing UV channels are not a standard

width (the original provider has since gone out of business), and neither

manufacturer was willing to customize its system.

“City staff and the city engineer have been working with Spectral

Innovations Ltd., who are willing to make a custom unit, the price of which

is less than the previous low bid,” Winkel said. Since the installation will

be done by an electrical contractor, and must be done during low flow

periods (August to September), part of the cost for the $268,605 project

will be paid this fiscal year, with the remaining funds included in next

fiscal year’s budget, Winkel said.

The city has been granted an extension by DEQ, since additional efforts by

the wastewater plant crew have resulted in the plant meeting its discharge

requirements.

![]() March 17, 2009:

Ultraviolet light could beat hospital TB

March 17, 2009:

Ultraviolet light could beat hospital TB

Telegraph.co.uk

Installing ultraviolet lights in hospital wards and waiting rooms could stop tuberculosis spreading, a study shows.

Ultraviolet light could help beat TB on wards in hospitals, say scientists Photo: MARTIN POPE

The rays damage the bacteria's DNA so they cannot infect people, grow or divide and are already used in ambulances and operating theatres as a disinfectant.

Researchers found 35 per cent of guinea pigs given air straight from a ward of 69 TB patients became infected themselves - compared to 9.5 per cent of animals that breathed in the same oxygen that was first exposed to UV radiation.

They say TB bacteria - including drug-resistant strains - can be killed

by hanging a shielded UV light from the ceiling with a fan to mix the air.

Dr Rod Escombe, of Imperial College London, said: "When people are crowded

together in a hospital waiting room, it may take just one cough to infect

several vulnerable patients.

"Our previous research showed that opening windows in a room is a simple way

to reduce the risk of tuberculosis transmission, but this is

climate-dependent - you can't open the windows in the intensive care ward of

a Siberian hospital for example."

The rate of TB infection in the UK and other western countries is relatively

low and people who are infected can be treated using antibiotics.

But people are more likely to die from the disease in developing countries

like Peru because there are limited resources for isolating patients,

diagnosing them quickly and starting effective treatment.

Dr Escombe, whose findings are published in PLoS (Public Library of Science)

Medicine, said: "Also, the prevalence of drug-resistant TB is much higher in

the developing world. Preventing infection is much easier and cheaper than

treating a patient with tuberculosis."

Plans are already underway to install upper room UV lights in the chest

clinic at St Mary's Hospital, London, which will be the first hospital to

have them in the UK.

Dr Cath Noakes, of the University of Leeds' Faculty of Engineering, said:

"The lights must be set high enough to ensure patients and health workers

are not overexposed, but if the lights only treat air at that level, there

will be little benefit.

"To be most effective, ventilation systems need to create a constant flow of

treated air down to patient level, and potentially infected air up towards

the lights."

![]() February

24, 2009:

High Growth Reported for the UV LED Market

February

24, 2009:

High Growth Reported for the UV LED Market

Reportlinker.com

UV LEDs challenge the traditional $500M UV lamp business

UV business is a market of about $500 million with traditional UV lamp

technology. Thanks to its compactness, lower cost of ownership and

environmental friendly composition, it is expected that UV LED will replace

traditional lamps and also will open the door to many new applications,

especially portable ones.

In 2008, LEDs in the UV A/B spectrum were the dominant device in the

sub-400nm applications. More than 90% of the UV LED market (outside of R&D)

was covered by UV curing, counterfeit detection, medical and instrumentation

applications requiring UV A/B sources. The remaining 10% was allocated to

Air & Water purification with again a great portion of UV A-based LED source

for photocatalytic air purification.

UVA LEDs dominate today but UVC LEDs will lead the market tomorrow

Key applications for UVA are UV curing, document/banknote verification,

photocatalyst air purifier, medical phototherapy. Among those, the most

dynamic and important UVA lamp market is the UV curing business where UV LED

can definitely compete with traditional mercury lamps:

Market size is big ($120M) and with growth of about +10 % due to the

advantage of UV curing technology over traditional technology (speed, green

coating).

Many new players have emerged over the past 5 years at the system and LED

packaging level

The power output available has greatly increased and several Watts/cm² will

be available in 2009-2010.

There were high hopes about UVC applications (disinfection, purification

market) two years ago but real applications are still missing due to

significant technical and economic challenges for UV LEDs: power output,

efficiency, lifetime and cost. Hence UVC players are now focusing on UVA

The first UVC LED applications are mostly for scientific analytical

instruments. It is expected that the first large-scale sales for the

disinfection market will appear in 2010 on existing markets and also new

Point of Use or portable applications where compactness is a key issue.

Growth of the UVC market is strongly connected to the availability of AlN

bulk substrates that could theoretically multiply by 100 the LED chip

optical power output. Several players expect to provide AlN wafers in volume

at the end of 2009. Hence, time to market for UVC applications based on AlN

would probably be in 2011-2012.

We also observe a strong trend where AlN companies are now extending their

activities to UV LEDs to capture more added-value along the supply-chain.

According to the high potential UVA LED business in UV curing, augmented by

the growing market demand in water & air disinfection, we forecast a

cumulated $250M UV LED market in 2015.

![]() February

18, 2009:

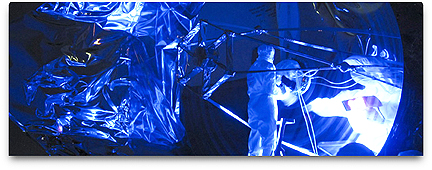

Herschel Bathed In UV To Ensure Cleanliness

February

18, 2009:

Herschel Bathed In UV To Ensure Cleanliness

SatNews.com

The

Herschel space telescope has completed what could be called the "blue phase"

of its pre-launch preparations for Arianespace's next Ariane 5 mission, with

the spacecraft's mirror inspected for cleanliness using ultraviolet light.

The

Herschel space telescope has completed what could be called the "blue phase"

of its pre-launch preparations for Arianespace's next Ariane 5 mission, with

the spacecraft's mirror inspected for cleanliness using ultraviolet light.

This activity, which is part of verifications to ensure the

3.5-meter-diameter mirror is free of particles after it was cleaned earlier

this month, occurred in the S1B facility at Europe's Spaceport, where

Herschel is being readied for an April 16 liftoff from French Guiana. As the

largest space telescope of its kind ever built, Herschel will investigate

how stars and galaxies are formed, as well as provide information on how

they continue to evolve. Its large mirror was built by joining 12 pieces

into one single element, which was ground, lapped and polished to the

correct shape — and then coated with a reflective aluminum layer.

Herschel is part of the European Space Agency's space science program, and

it will be launched by the next Ariane 5 with another of the agency's

spacecraft — Planck, which will observe the Cosmic Microwave Background to

provide new data on how the universe began. The Herschel spacecraft arrived

at the Spaceport in early February, and is to be joined by Planck, which is

en-route for a landing this evening (February 18) at the country's

Rochambeau International Airport near the capital city of Cayenne. Ariane

5's April 16 flight will deploy Herschel and Planck into very elliptical

orbits, enabling both spacecraft to follow transfer trajectories for their

voyage to the second Lagrange point (L2) of the Sun-Earth system.

![]() January

28, 2009:

Bottle disinfection — without the byproducts

January

28, 2009:

Bottle disinfection — without the byproducts

WaterTechOnline.com Volume 32, Issue 1 By Marc J. Scanlon

UV can be used for primary disinfection, or as a backup for other methods.

Until now ozone disinfection has been a popular method of disinfecting

bottled water. While ozone has a number of advantages, it is coming under

increasing scrutiny because of concerns about disinfection byproducts —

particularly bromate, a suspected carcinogen — which can form as a result of

the ozonation process.

Bromide ions occur naturally in many spring waters and are completely

harmless. However, if their levels are high, ozone can facilitate their

conversion into bromate.

An alternative method gaining acceptance across the whole spectrum of food

and beverage industries is ultraviolet (UV) disinfection. UV kills all known

spoilage microorganisms, including bacteria, viruses, yeasts and molds (and

their spores) without producing any undesirable disinfection byproducts. It

is a low-maintenance, environmentally friendly technology which eliminates

the need for chemical treatment while ensuring very high levels of

disinfection.

How UV disinfection works

UV is the part of the electromagnetic spectrum between visible light and

X-rays. The specific portion of the UV spectrum between 185 and 400

nanometers (nm), also known as UV-C, has a strong germicidal effect, with

peak effectiveness at 265 nm. At these wavelengths UV kills microorganisms

by penetrating their cell membranes and destroying the DNA, making them

unable to reproduce and effectively killing them.

A typical UV disinfection system consists of a UV lamp housed in a

protective quartz sleeve which is mounted within a cylindrical stainless

steel chamber. The water to be treated enters at one end and passes along

the entire length of the chamber before exiting at the other end. Liquids

that can be effectively treated with UV include spring, surface or municipal

water; filtered process water; and clear viscous sugar syrups and effluent.

Feed liquids for UV should be sufficiently low in dissolved or suspended

particles that they allow effective penetration of the UV light.

There are two main types of UV technology, based on the type of UV lamps

used: low pressure and medium pressure. Low-pressure lamps have a

monochromatic UV output (limited to a single wavelength at 254 nm), whereas

medium-pressure lamps have a polychromatic UV output (with an output between

185 and 400 nm).

Generally speaking, low-pressure systems are best suited for small,

intermittent flow applications, while medium-pressure technology is better

suited to higher flow rates.

UV disinfection’s advantages over alternative methods include the fact that,

unlike chemical biocides, UV does not introduce toxins, residues or

byproducts into the process and does not alter the taste, odor or pH of the

water.

UV treatment can be used for primary water disinfection or as a backup for

other water purification methods such as carbon filtration, reverse osmosis

or pasteurization.

As UV has no residual effect, its best position in a treatment system is

immediately prior to the point of use. This ensures that incoming

microbiological contaminants are destroyed and there will be a minimal

chance of post-treatment contamination.

UV on a bottling line

Incoming water supplies: Although natural springs and municipal water

supplies are normally free from harmful or pathogenic microorganisms, this

should not be assumed. Surface water from wells, rivers or lakes —

particularly in livestock farming areas — can be contaminated and should be

disinfected.

CIP (Clean-in-Place) rinse water: It is essential that the CIP final rinse

water used to flush out foreign matter and disinfecting solutions be

microbiologically safe. Fully automated UV disinfection systems can be

integrated with CIP rinse cycles to ensure final rinse water does not

reintroduce microbiological contaminants. Medium-pressure lamps are ideal

for this application because of their mechanical strength, meaning they are

not affected by any sudden changes in the temperature of the CIP water, such

as when hot (80 degree C, or 176 F) liquid is instantly followed by cold (10

degrees C, or 50 F).

Filter disinfection: Stored reverse osmosis (RO) and granular activated

carbon (GAC) filtrate can be a breeding ground for bacteria. UV is an

effective way of disinfecting both stored RO and GAC filtered water and has

been used in the process industries for many years.

Dechlorination: GAC filters are also often used to dechlorinate process

water, removing the “off” flavors often associated with chlorine

disinfection. Placing UV systems ahead of GAC filters used for

dechlorination improves the performance of the filters (by reducing filter

biofouling), resulting in longer carbon runs and lower operating costs.

Other plant UV applications

Surface disinfection systems are used to reduce microbial counts on all

kinds of packaging, including glass and plastic bottles, cans, lids and

foils. By irradiating the surfaces with UV prior to filling, spoilage

organisms are eliminated, extending the shelf life of the product and

reducing the risk of contamination.

Sugar syrups used as flavorings can be a prime breeding ground for

microorganisms. Although syrups with a very high sugar content do not

support microbial growth, any dormant spores may become active after the

syrup has been diluted. Treating the syrup and dilution water with UV prior

to use will ensure any dormant microorganisms are deactivated.

Tank head space disinfection: UV systems can be used to disinfect

displacement air for pressuring tanks or pipelines holding perishable

fluids. Storage tanks are particularly susceptible to bacterial colonization

and contamination by airborne spores. To prevent this, immersible UV

treatment systems have been designed to fit in the tank head air space and

disinfect the air present.

Simple to maintain

Meeting the increasingly rigorous hygiene standards required in the

production of bottled water is becoming more of a challenge, particularly

with growing concerns about byproducts such as bromate. Customers are also

demanding a product that has not been treated with chemicals.

For those producers seeking to improve the quality of the end product, UV is

an economic, realistic option. It is a well-established method of

disinfecting drinking water throughout the world and is widely used for

high-purity applications such as pharmaceutical processing and semiconductor

manufacturing, where water of the highest quality is required.

UV disinfection systems are easy to install, with minimum disruption to the

plant. They need very little maintenance, the only requirement being

replacement of the UV lamps every 8,000 hours, depending on use. This is a

simple operation that takes only a few minutes and can be carried out by the

general maintenance staff.

![]() January

14, 2009:

WaterHealth Lands $10M for UV Water Purification

January

14, 2009:

WaterHealth Lands $10M for UV Water Purification

Greentechmedia.com

The Series D funding will help the Irvine, Calif.-based company expand sales of its combination filtration and ultraviolet light water purification technology. Water purification is a growing business both in developed countries and the third world.

WaterHealth International Inc., has a deal for poor rural villages around

the world – we'll help you borrow money to buy our water purification

systems, and then we'll stick around to make sure they're run properly.

The Irvine, Calif.-based company announced this week it has raised $10

million in a series D round led by previous investors Dow Venture Capital

and SAIL Venture Partners.

That brings total investment for WaterHealth to about $26 million, CEO

Tralance Addy said Wednesday. The company hopes to raise another $10 million

by March.

WaterHealth is among a number of companies, from startups to giants like

Bechtel Corp., General Electric and Siemens, that are focusing on the

looming worldwide water crisis.

An estimated 1.1 billion people worldwide lack access to clean drinking

water, and the United Nations has warned that population growth and water

depletion could lead to water shortages for 2.7 billion people by 2030.

![]() January

8, 2009:

Degrémont Technologies-Ozonia launches powerful ultraviolet reactor for

drinking water treatment

January

8, 2009:

Degrémont Technologies-Ozonia launches powerful ultraviolet reactor for

drinking water treatment

Environmentalexpert.com

Degrémont Technologies-Ozonia won a big success, at the Pollutec

exhibition in France, with the presentation of its last UV reactor: AQUARAY®

H2O 36’’.

AQUARAY® UV disinfection systems offer the better compromise between the

higher efficiency and the smaller footprint with low or medium pressure UV

reactors.

To answer to the market demands for very large drinking water plants,

Degrémont Technologies- Ozonia introduces AQUARAY® H20 36’’(DN900), a

powerful UV reactor with an up to 7 000 m3/h capacity, environmentally safe

and recognized as effective for a wide range of bacteria, viruses and

parasites like Cryptosporidium Parvum or Giardia Lamblia.

The AQUARAY® H2O 36’’ inline cross flow reactor uses 10 high density medium

pressure lamps to offer compact footprint and easy integration on new or

existent water treatment lines.

Engineered with the advanced CFD (Computerized Fluid Modelling) software to

determine optimum lamp spacing and optimize its efficiency, the system

provides consistent and reliable disinfection.

UV treatment allows maintaining high quality standards of the water

delivered, reduces the risk of waterborne diseases and complies with new

regulations of pathogens and bromate limits:

• The AQUARAY® H2O reactors are used as a final barrier to disinfect water

by inactivating pathogenic microorganisms like viruses, bacteria and

parasites. UV lights are particularly effective for chlorine resistant

microorganisms such as Cryptosporidium and Giardia, even at low doses.

• UV treatment allows respecting the new maximal limit of bromate

concentrations lowed to 10 μg/l (against 25 μg/l) from 25 December 2008.

In addition, the AQUARAY® H20 is under the process of being validated for

the disinfection of drinking water and for the inactivation of

Cryptosporidium and Giardia.

By anticipating municipal needs with a powerful and environmentally safe UV

reactor, Degrémont Technologies–Ozonia secures its leadership position and

confirms the advanced technologies of its solutions.

![]() January

6, 2009:

Calgon Carbon Awarded San Francisco UV Contract

January

6, 2009:

Calgon Carbon Awarded San Francisco UV Contract

PRNewswire

Calgon Carbon Corporation (NYSE: CCC) announced today that it has been

awarded a contract by PCL Civil Constructors, Inc. to supply Sentinel(R) UV

Disinfection Systems (UV systems) at the City of San Francisco's Tesla

Portal drinking water plant. The contract is valued at $5.0 million.

Twelve Sentinel(R) Chevron 48 reactors (Chevron 48), scheduled to be

installed beginning in early 2010, will treat up to 320 million gallons of

drinking water per day. The Chevron 48, which is Calgon Carbon's latest

addition to its Sentinel(R) product line, can treat up to 45 million gallons

of water per day. The company's ongoing product advancements support San

Francisco's goal to provide safe drinking water to its customers and to

comply with federal regulations for the control of Cryptosporidium, Giardia,

and other waterborne organisms.

Earlier in 2008, the company was awarded contracts to supply a total of 14

Sentinel(R) UV Disinfection Systems for Singapore's Johor River Water

Treatment Works and Indianapolis' White River Facility. When installation of

those systems is complete, they will have the capability of treating more

than 350 million gallons of drinking water per day.

Commenting on this announcement, Jim Sullivan, Calgon Carbon's vice

president of UV Technologies said, "We are pleased that the City of San

Francisco selected our newest Sentinel(R) design to meet their disinfection

needs. The commercialization of the Chevron 48 exemplifies our successful

product development efforts in UV technology as well as our strong position

in the growing, drinking water disinfection market worldwide."

![]() December

12,

2008: Sharper

Image Making A Comeback At CES

December

12,

2008: Sharper

Image Making A Comeback At CES

CRN.com ChannelWeb, by Andrew R Hickey

Sharper Image, the struggling consumer electronics retailer that met its

demise after filing for Chapter 11 bankruptcy protection in February (2008),

is planning a comeback at the Consumer Electronics Show (CES) in Las Vegas

next month.

In an e-mail sent to CES attendees on Friday, Sharper Image said it will

launch more than 20 new products that will be available in a "wide range of

retail stores in 2009."

"Please join us for the much-anticipated launch of the 'New Era of Sharper

Image,'" the e-mail stated.

"Our all new electronics line brings back to the marketplace the best things

that the Sharper Image brand represents - innovation, premium performance

and unique designs," the e-mail continued. "We'll be relaunching with a

range of wireless audio, bedside audio, portable audio and speaker systems

products. "

Earlier this year, San Francisco-based Sharper Image filed for bankruptcy

after experiencing declining sales since 2004. The company recorded net

losses in fiscal 2005 to 2007, which continued into 2008. Dwindling consumer

spending and negative publicity surrounding its Ionic Breeze air purifiers

were integral to the bankruptcy filing.

At its peak, Sharper Image had 186 stores nationwide, while also selling

through a monthly catalog and a Web site. As of June 1, 2008 96 Sharper

Image stores had completed liquidation and were closed. The remaining stores

and assets were bought out by Hilco Merchant Resources and Gordon Brothers

Group. Since then, all remaining stores have been shuttered.

On Friday, hinting at its pending attempt at a comeback, Sharper Image's Web

site simply read: "Sorry to keep you in the dark. But, there's something big

coming. Soon. Stay tuned."

![]() December

8,

2008:

Disinfecting Marine Vessel Ballast Water With UV

December

8,

2008:

Disinfecting Marine Vessel Ballast Water With UV

EnvironmentalExpert.com

To assist operators of cruise ships, tankers, semi-submersibles, jack-up

rigs and other large ocean-going vessels to meet the International Maritime

Organisation’s (IMO’s) impending ballast water discharge requirements, UV

disinfection specialist Hanovia has partnered with three of the world’s

leading systems integrators to provide validated, on-board water treatment

systems that are easy to install and use.

All ocean-going vessels take on water to provide ballast and stability. It

is usually taken on in coastal port areas and transported to the next port

of call – sometimes on the other side of the world – where it may be

discharged. Much of this water contains marine microorganisms such as

zooplankton, algae, bacteria and the eggs, cysts and larvae of various

species. While many die in transit, some survive and invade the local marine

environment, out-competing native species and causing serious damage to

native ecosystems. Environmental damage caused by ballast water is now

regarded as one of the greatest threats to the world’s oceans.

Two methods have been proposed to combat this problem: onboard ballast water

treatment and ballast water exchange. As the name suggests, ballast water

treatment involves treatment of ballast water prior to discharge, while

ballast water exchange involves ballasting and de-ballasting in the open

ocean before coming into ports and coastal waters. This open ocean exchange

is not an ideal solution as it is potentially unsafe and can destabilise the

vessel. Also, because existing ballast water exchange systems do not

completely drain the tanks, sediment and a residual amount of water can

remain, leaving behind non-indigenous species which could be discharged in

port later.

As well as being unsafe, open ocean ballast water exchange is difficult to

regulate and monitor, so many operators simply do not do it. Because of this

the IMO is setting much tougher standards to control ballast water practices

and has published two Conventions to tackle the problem. The first is the

International Convention for the Prevention of Pollution from Ships (MARPOL),

dealing with waste and sewage discharge from ships (ratified in 2003), and

the second is the Ballast Water Management (BWM) Convention, to control the

spread of alien species (due for ratification in 2009). Under the BWM

Convention, vessels will have to treat all ballast water so that discharges

contain less than 10 viable organisms per cubic metre equal to or greater in

size than 50 µm in size.

To help operators confront these requirements Hanovia, in tandem with the

leading systems integrators, has devised a UV disinfection system that, in

conjunction with a filter, kills or removes virtually all microorganisms

present in ballast water. The combined system comprises a high intensity,

medium pressure UV disinfection unit and an automatic back-flush filter.

After passing through the filter to remove larger organisms, the ballast

water flows into the UV chamber to destroy smaller organisms. During

de-ballasting, the water bypasses the filter but again flows through the UV

chamber where further irradiation kills any remaining microorganisms.

The entire system has a very small footprint and can be mounted at any

angle, making it easy to install even in the confined spaces of a vessel’s

equipment room. Once installed, the system requires little effort to operate

by the crew. It can be controlled by a master PLC unit which can be

integrated into the vessel’s machinery automation network. The UV unit is

equipped with automatic wipers to keep the UV lamps clean, and the only

maintenance required by the crew is the replacement of the UV lamps once a

year and occasional preventative maintenance procedures.

![]() November

25,

2008:

Crystal IS, Inc. Wins $800,000 Department of Defense Grant to Develop UV-LEDs

November

25,

2008:

Crystal IS, Inc. Wins $800,000 Department of Defense Grant to Develop UV-LEDs

Finchannel.com

Crystal IS, Inc., the world's leading manufacturer of ultraviolet light

emitting diodes (UV LEDs) based on aluminum nitride (AlN) substrate

technology, today announced it will receive an $800,000 appropriation from

the U.S. Department of Defense to advance development of large AlN crystals

for effective deep ultraviolet sources.

"Our unique technology allows us to manufacture UV LEDs with unsurpassed

performance at truly commercially viable costs," said Crystal IS CEO Steven

Berger. "This grant serves as yet another validation of using AlN-based UV-LEDs

to enable cleaner water and air for consumer, industrial and government

customers."

As part of the program, Crystal IS will partner with the Army Research