|

UV News & Articles | |

| Contact | Login | ||

| profile | uv systems | uv science facts | press releases | uv info | business programs |

UV News

|

|

|

UV News Note: These UV news items have been gleaned from the Internet. The UV news are partially reproduced as found. AAW takes no responsibility for their accuracy. The links to the full UV articles were active at the time of posting.

UV News

![]() January 2019:

kathy ireland® Discusses The

Future of Light with American Air & Water

January 2019:

kathy ireland® Discusses The

Future of Light with American Air & Water

Worldwide Business with kathy ireland®

Los Angeles, CA - January 15, 2019 - Worldwide Business with kathy ireland®

is pleased to announce an exclusive interview with Warren Lynn, CEO of

American Air & Water to discuss their custom built

UV systems.

Founded in 2002, the company designs and delivers ultraviolet solutions

through germicidal UVC systems for disinfection of air, surfaces, water and

liquid sugar. They are used by industrial, commercial, municipal and

residential customers to control the spread of germs while improving energy efficiency.

"Our business for the last 20 years has been all about air, water, surfaces

and food processes," says Lynn. "It's all about light and what's under the

sun. We've developed a new process of light that helps us take care of the

air we breathe, water we drink and food we eat. This opens up opportunities

for businesses, especially a disruptive business in the healthcare industry."

Different colors can affect our mood. The importance of light changes by the

day. American Air & Water is working to improve the future of farming with

smart light technology.

"Making sure we have the resources to protect our way of life is key," says

J.L. Haber, Vice President of Programming for Worldwide Business. "American

Air & Water is showing us all how to do it right."

For more information about American Air & Water, visit

Americanairandwater.com and tune in to Fox Business Network as sponsored

content on Sunday, January 20, 2019 at 5:30pm EST and Bloomberg

International on Saturday, January 19, 2019 at 7:00pm GMT and Sunday,

January 20, 2019 at 10:00am D.F. and 2:30pm HKT.

About Worldwide Business with kathy ireland®

Worldwide Business with kathy ireland® is a weekly half-hour show featuring

global executives sharing their business insights and framing the

opportunities shaping their industries. Hosted by a business mogul, Kathy

Ireland interviews some of the brightest minds in business today. The show

broadcasts on Fox Business Network as part of their sponsored content line

up and globally on Bloomberg International. Worldwide Business with kathy

ireland® extends beyond the weekly on-air program with digital content

delivered on various video platforms and across social media.

Visit www.tvwwb.com for

detailed airing schedules or check local listings.

Tune in to Bloomberg International on Saturday, January 19, 2019 at 7:00pm

GMT and Sunday, January 20, 2019 at 10:00am and Fox Business Network on

Sunday, January 20, 2019 at 5:30pm EST

![]() June 2017:

Ultraviolet Light Means Efficiency, Cost Savings In Kansas

June 2017:

Ultraviolet Light Means Efficiency, Cost Savings In Kansas

By Sara Jerome / Water Online

Germicidal UV Water Disinfection

Image credit: see note 1

Wastewater operators at a facility in Kansas recently found that the

route to greater efficiency traveled through their disinfection system.

Electricity costs at the plant have been cut in half following upgrades,

officials say.

Wichita’s Lower Arkansas River wastewater treatment plant “has seen

significant cost savings since upgrading its ultraviolet disinfection system

last year, its supervisor says. The plant is now able to treat more

wastewater, which is then released into the Arkansas River,” KMUW reported.

The plant upgraded from a medium ultraviolet treatment system to a

high-intensity, low-pressure system last year, the report said.

Jamie Belden, operation supervisor for the City of Wichita's sewage

treatment division, explained the new system: “He said the ultraviolet light

doesn’t kill bacteria, but it alters the DNA so bacteria can’t reproduce. He

says the new system needs less maintenance, and workers are able to treat 80

million gallons of water per day instead of 60 million,” KMUW reported.

Belden said: "By putting that system in, not only are we able to disinfect

more wastewater, but over about a two-year period, we’ll recover our

investment completely just in energy cost.”

Advocates of ultraviolet disinfection stress the advantages of reducing the

use of chemicals, including chlorine, a disinfectant, and sulfur dioxide,

which removes chlorine, according to MLive. Jackson, MI, for instance,

approved a deal to use UV light disinfection at the plant last year, the

report said.

The city made a deal with Wade Trim to design the system for $210,000.

The city expects power bills to go up but chemical costs to plummet, the

report said. The city expects to save $100,000 on chemicals and to save

money overall. The full project is expected to cost between $1.3 and $1.5

million.

"The use of an ultraviolet disinfection system would eliminate the use of

(chlorine and sulfur dioxide) in the process. I thought it was time for us

to take a look at it and see if it's appropriate for our system,” said Todd

Knepper, director of public works said, per the report.

Chlorine is sometimes criticized for posing safety hazards, but many water

industry professionals defend its use. The Water Quality and Health Council,

sponsored by the American Chemistry Council, points out that chlorine

disinfection revolutionized drinking water treatment. The group notes that

chlorine is a potent germicide and treats taste, odor, biological growth,

and chemicals.

Note 1: Image credit: "electricity," Stanislav Sedov © 2016, used under an Attribution 2.0 Generic license: https://creativecommons.org/licenses/by/2.0/

![]() June 2015:

UV Light Cuts Spread Of Tuberculosiss

June 2015:

UV Light Cuts Spread Of Tuberculosiss

By Imperial College London / ScienceDaily

Ultraviolet lights could reduce the spread of tuberculosis

in hospital wards and waiting rooms by 70%, according to a study, published

in PLoS Medicine. The study, which explored the transmission of tuberculosis

(TB) from infected patients to guinea pigs, suggests that installing simple

ultraviolet C (UVC) lights in hospitals could help reduce the transmission

of TB, including drug-resistant strains.

Every year, over nine million people are infected with tuberculosis and

nearly two million people die from the disease, according to the World

Health Organisation. Infection rates are particularly high in places where

vulnerable people are crowded together, such as hospitals, homeless shelters

and prisons.

When a tuberculosis patient coughs, bacteria are sprayed into the air in

tiny droplets, floating around the room and infecting other patients,

visitors and healthcare staff. These bacteria can be killed by hanging a

shielded UVC light from the ceiling with a fan to mix the air, say the

researchers, from Imperial College London, the University of Leeds, Hospital

Nacional Dos de Mayo, Lima, Perú and other international institutions.

UVC light kills tuberculosis bacteria, including drug-resistant strains, by

damaging their DNA so they cannot infect people, grow or divide. It is

already used at high intensity to disinfect empty ambulances and operating

theatres.

Dr Rod Escombe, the study's principal investigator from the Wellcome Trust

Centre for Clinical Tropical Medicine at Imperial College London, said:

"When people are crowded together in a hospital waiting room, it may take

just one cough to infect several vulnerable patients. Our previous research

showed that opening windows in a room is a simple way to reduce the risk of

tuberculosis transmission, but this is climate-dependent – you can't open

the windows in the intensive care ward of a Siberian hospital for example."

"Thankfully, the rate of tuberculosis infection in countries like the UK is

relatively low and people who are infected can be treated using antibiotics,

which are readily available here. People are more likely to die from the

disease in developing countries like Perú, because there are limited

resources for isolating patients, diagnosing them quickly and starting

effective treatment. Also, the prevalence of drug-resistant TB is much

higher in the developing world. Preventing infection is much easier and

cheaper than treating a patient with tuberculosis," added Dr Escombe.

Plans are already underway to install upper room UV lights in the chest

clinic at St Mary's Hospital, part of the Imperial College Healthcare NHS

Trust, which will be the first hospital to have them in the UK.

Introducing UVC lights could be a relatively low-cost measure, say the

researchers. Currently, a typical UVC ceiling light costs around US$350 and

replacement bulbs cost from US$25. The researchers are now working to

develop more affordable US$100 units.

The impact of UV lights is greatest when combined with careful management of

the air flow on the wards, as Dr Cath Noakes from the University of Leeds'

Faculty of Engineering explains: "The lights must be set high enough to

ensure patients and health workers are not overexposed, but if the lights

only treat air at that level, there will be little benefit. To be most

effective, ventilation systems need to create a constant flow of treated air

down to patient level, and potentially infected air up towards the lights."

To reach their conclusions, scientists hung UVC lights in a hospital ward in

Lima, Perú where 69 patients with HIV and TB were being treated. The

researchers pumped air from the ward up to a guinea pig enclosure on the

roof of the hospital for 535 consecutive days. The guinea pigs were split

into three groups of approximately 150: the first group received air exposed

to the UV lights in the ward, the second group received ward air treated

with negative ionisers, and the third control group was given untreated air

straight from the ward. The guinea pigs were given skin tests for

tuberculosis once a month.

By the end of the experiment, 35% of the control group were infected with

TB, compared to 14% of the ionised air group and 9.5% of the UVC group. 8.6%

of the control group developed the active form of the disease after being

infected with TB, compared to 4.3% of the ionised air group and 3.6% of the

UVC group.

![]() May 2015:

IAQ - Increase Airflow with Duct Maintenance

May 2015:

IAQ - Increase Airflow with Duct Maintenance

By Thomas A. Westerkamp

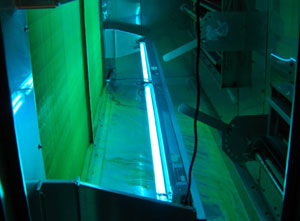

Germicidal UV Air Disinfection

In-Duct UV Installation

To increase airflow, technicians can start by cleaning air ducts.

Build-up of dust and other particulates can cause turbulence, which reduces

air volume. This activity provides a benefit beyond limiting turbulence. It

also eliminates a source of pollution - the reintroduction of particulates

into the air when they break off the duct walls.

If ducts contain moisture, technicians can get rid of hidden mold by

cleaning the ducts with electric brushes and vacuuming the residue. Adding

ultraviolet lights to the area in which water forms in the duct can

eliminate the mold problem.

Finally, high-efficiency particulate air (HEPA) filters can resist most

particulates, but technicians will have to make sure an adequate volume of

air flows through the filters.

![]() 19 March 2015:

Stop TB Partnership initiative reveals surprising results - 1 in 9 staff

tested positive for latent TB infection

19 March 2015:

Stop TB Partnership initiative reveals surprising results - 1 in 9 staff

tested positive for latent TB infection

Dr Lucica Ditiu, Executive Secretary, Stop TB Partnership

47 colleagues were tested for latent TB infectionn

Dear colleagues, partners and stakeholders,

Last week we shared worldwide the fact that 47 colleagues working at the

Stop TB Partnership Secretariat, UNOPS, and the Global Fund to Fight AIDS,

Tuberculosis & Malaria took an Interferon Gamma Release Assay (IGRA test)*

to determine if the person is infected with latent TB.

It was an effort to show globally that it is important for everyone to know

what is happening with their bodies -- to show that people infected with TB

are everywhere and to show that there should be no stigma associated with

the TB infection. It was also a very good opportunity for us to review the

literature, guidelines, to have discussions and counseling about the

testing for TB infection and the role of TB prevention. It generated a lot

of interest and opportunities for people to discuss TB, the infection and

the active disease.

We are now in a position to share the results of our test: out of the 47

people tested, 5 were positive for latent TB infection, and the rest of the

tests came back negative. The 5 positive colleagues - 3 women and 2 men -

consist of 3 who are from high burden countries (2 from Africa and 1 from

Asia), 1 from Western Europe and the last from North America. While some of

the colleagues with positive results were aware and expecting the result, it

came as a surprise for the colleagues from Western Europe and North America

as none of them had lived in any of the high burden countries, having only

visited occasionally.

I discussed the results individually with each of the positive colleagues

and advised on next steps. If anything, this test showed a high infection

rate in a group of professionals based in Geneva (1 in 9). This was

certainly not intended as an epidemiological survey or as a medical

screening exercise. It demonstrated how little we understand the TB

infection, the body's reaction and the TB disease. Nevertheless, the process

and the results we obtained have got us thinking on the role that TB

infection screening and TB prevention shall play in the present and future

of TB control. More importantly, we realized that testing for infection and

assessing the need for TB prevention goes beyond TB control measures, but

that it becomes an individual choice and right to knowledge of risk.

With this initiative, we at the Stop TB Partnership Secretariat stepped in

uncharted territory. We were not aiming at providing answers but rather at

eliciting questions. How can we advance research including basic research to

understand more and develop new tools? How do we ensure that knowledge and

access to TB prevention, diagnostics and treatment becomes an individual

right regardless of economic barriers, access to testing and treatment? And

how do we balance the need for cost effective population measures with the

individual right to knowledge of his/her TB risk, infection and disease?

These are crucial questions if we truly want the End TB Strategy to be a

successful one and we will address some of them in the new Global Plan to

Stop TB 2016-2020.

I take this opportunity to give a heads-up on a great White Paper that Stop

TB USA have developed and will be launching on World TB Day. The paper calls

for a more robust national response focusing on diagnosing and treating TB

infection in order to prevent future cases of TB and to stop its

transmission.

With best regards,

Dr Lucica Ditiu

Executive Secretary

Stop TB Partnership

![]() HPAC News:

Ultraviolet (UV-C) Energy and the Persistence of Building Performance

HPAC News:

Ultraviolet (UV-C) Energy and the Persistence of Building Performance

By FORREST FENCL

Germicidal UV systems for cooling coil disinfection

UV-C lighting maintains the cleanliness of wet HVAC components;

minimizes, if not eliminates, the use of chemicals; and keeps energy and

water use in check.

Getting everything in a building to work to the designer’s intent and in

accordance with the owner’s project requirements is one thing. Maintaining

that level of performance is another.

Among the keys to the persistence of HVAC performance is the cleanliness of

cooling coils, drain pans, and other “wet” components. When mold, biofilm,

and other organic compounds are allowed to build up:

• Indoor air experiences odors and the spread of respiratory irritants,

pathogens, and allergens.

• Airflow through coils becomes restricted and fouled (lost heat

transfer), deteriorating comfort and energy performance.

• Equipment and material life is shortened, and maintenance requirements

increase.

Any of these outcomes threatens the “three Es” of a building’s—a green one’s

in particular—bottom line: energy, efficiency, and economy.

One technology that meets the challenges of regular cleaning of wet HVAC

components, as well as minimizing, if not eliminating, the use of chemicals

and keeping energy and water use in check, is ultraviolet-C (UV-C) lighting.

ASHRAE Handbook—HVAC Applications suggests UV-C reduces mold and biofilm,

coil pressure drop, and coil-cleaning functions without the use of

chemicals. Further, it states use of UV-C can increase airflow and

heat-transfer coefficient and reduce both fan- and refrigeration-system

energy use. Savings of 10 to 30 percent have been reported once capacity is

restored.

The UV-C wavelength easily keeps a new coil clean and degrades organic

materials that have deposited on existing coil fin and tube surfaces. As a

result of this cleaning action, a coil’s “open area” remains or returns to

the designed performance standards. The pressure drop and velocity of the

air between coil fins is optimized, while fin and tube surfaces are kept

clean to maximize system heat-exchange efficiency and rate. Many

original-equipment manufacturers believe UV-C could contribute to as-built

capacity for the life of a system, if the UV-C technology is maintained.

Energy

According to ASHRAE, maintaining design air leaving wet-bulb temperature is

fundamental to maintaining occupied spaces in the “comfort zone.”

Maintaining this standard of thermal comfort is one of the most important

goals of a properly designed and maintained HVAC system (ANSI/ASHRAE

Standard 55, Thermal Environmental Conditions for Human Occupancy). Cooling

coils reduce the absolute humidity of the air processed. The below-dew-point

coil surface condenses water vapor from the recirculated air to reduce

relative humidity in a conditioned space. This drier air of, typically,

40-percent to 60-percent humidity improves comfort in the occupied space.

Chapter 60.8 of 2011 ASHRAE Handbook—HVAC Applications states, “By

suppressing the formation of biofilms (and in the worst cases, extensive

mold growth) on coils, coil irradiation should reduce airside pressure drop,

increase heat transfer coefficient, and reduce both fan and refrigeration

system energy consumption.”

Minor increases in air leaving wet-bulb temperature have dramatic effects on

system capacity and, thus, energy costs. For example, with a 20,000-cfm

system with an air entering wet-bulb temperature of 64°F and an air leaving

temperature of 53°F, an increase in air leaving wet-bulb temperature of

“only” 1°F results in a loss of air-conditioning capacity of 4.5 tons.

Within five to 10 years, increases in air leaving temperature of 3°F are not

uncommon.

Often, fan speed is increased to help compensate for lost air-conditioning

capacity. However, fan horsepower increases to the “cube” of revolutions per

minute. Thus, increasing fan speed consumes more energy than we realize.

However, it may be enough to satisfy capacity loss temporarily. If it is

not, further modifications are required.

Building engineers typically turn next to chilled-water temperature.

Lowering chilled-water temperature increases the temperature differential

between air and coil surfaces, increasing heat-transfer rate. The lowering

of chilled-water temperature requires an increase in energy use and often is

accompanied by the pumping of additional water. Increasing pump revolutions

per minute has the same consequences as increasing fan revolutions per

minute: a boost in horsepower to the cube of the increase.

All of the above makes an unquestionable case for keeping a coil perfectly

clean.

Indoor-Air Quality (IAQ)

UV-C helps to maintain or, in a retrofit, significantly improve IAQ. The

application of UV prevents the formation and reduces the dissemination of

several categories of organisms that can grow and/or spread in modern

air-handling systems. These include pathogens (viruses, bacteria, and fungi,

which can cause a range of diseases), allergens (bacteria and mold, which

can cause allergic rhinitis, asthma, humidifier fever, and hypersensitivity

pneumonitis), and toxins (endotoxins and mycotoxins, which can cause a

variety of toxic effects, irritation, and odors). According to both ASHRAE

and the U.S. General Services Administration, UV-C energy prevents microbial

“growth and transfer” into occupied spaces.

Occupant Comfort

With coils kept perfectly clean, heat-exchange efficiency and rate are

maintained at as-designed values. And with microbial growth and transfer

prevented, the air serving occupied spaces is not contaminated by products

associated with odor-producing biomatter. Both scientific and anecdotal

information is abundant in this area. Occupant surveys and comments

overwhelmingly side with a clean system.

Chemicals, Drains, and Water

Chapter 60.8 of 2011 ASHRAE Handbook—HVAC Applications states: “Conventional

methods for maintaining air handling system components include chemical and

mechanical cleaning which can be costly, difficult to perform, and dangerous

to maintenance staff and building occupants. Vapors from cleaning agents can

contribute to poor air quality, chemical run off contributes to ground water

contamination and mechanical cleaning can reduce component life.

Furthermore, the system’s performance can begin to degrade again shortly

after cleaning as microbial deposits reappear or reactivate.” The results

and concerns here are not always obvious. Coil cleaning does not get the

coil perfectly clean, regardless of the amount of water used. Contaminants

return and, each time, additional organic material is left behind.

Additionally, coil-cleaning chemicals contaminate drain waterways and air

streams, which are not consistent with the green-building theme, or

acceptable IAQ.

Maintenance

The use of UV-C in HVACR equipment has been shown to reduce maintenance and

associated costs. According to Chapter 60.8 of 2011 ASHRAE Handbook—HVAC

Applications, “Potential advantages of UV-C surface treatment includes

keeping surfaces clean ‘continuously ’rather than periodically, restoring

fouled surfaces, with no use of chemicals, and lower maintenance cost and,

potentially, better HVAC system performance.”

Conclusion

Of all of the complex matters owners and operators of buildings face,

keeping coils and drain pans clean need not be one of them.

![]() June 20, 2014:

The UV Uprising: How UV Disinfection Will Claw Its Way To Prominence

June 20, 2014:

The UV Uprising: How UV Disinfection Will Claw Its Way To Prominence

Wateronline.com by Sheldon Primus, MPA, COSS

Chlorination in all of its forms — gas, liquid, or solid — has been the

primary way for treatment plants to disinfect the treated wastewater. The

treatment plants that use gas chlorination must face federal regulatory

oversight in the form of a Risk Management Program (RMP). Liquid chlorine

plants trade in the regulatory oversight for a more expensive and less

effective product. While chlorine in its solid form is good for small

treatment facilities known as package plants (named for their mobility).

However, ultraviolet (UV) technology is rapidly altering the landscape of

disinfection throughout the industry.

Why UV Disinfection?

Though chlorine is widely accepted as a primary disinfection for more than a

century, the limitation of chlorine disinfection is increasingly

intolerable. The National Small Flows Clearinghouse (NSFC) at West Virginia

University (WVU) released a fact sheet on chlorine disinfection that

outlines the disadvantages of chlorine as:

• Chlorine residual is toxic to aquatic life and may require

dechlorination.

• All forms of chlorine are highly corrosive and toxic, making

handling, storage, and shipping a safety threat.

• Chlorine oxidizes organic matter that can sometimes create

harmful compounds to humans and the environment.

• Chlorine content in wastewater is increased.

• There are chlorine-resistant organisms in treated effluent.

Even small doses of chlorine are toxic to aquatic life, and there are no

long-term studies of the effect of dechlorinated effluents to the ecology.

Reuse applications, where the treated wastewater effluent is used as

irrigation or service water, can impact aquatic life with chlorinated

effluent. The upstream condition of the treatment plant plays an important

role of how much chlorine dosage must be added for disinfection. The

chlorine demand increases if the secondary effluent is nutrient-rich with

ammonia or nitrites, leading to more chlorine usage to get the same level of

disinfection.

The alternative disinfection system is UV irradiation, which is considered

one of the three mature methods of disinfection along with chlorine and

ozone. These methods are mature because they have existed for a considerable

amount of time. UV use has increased due to its high efficacy against

chlorine-resistant protazoae cryptosporidium and giardia and the prevention

of toxic chlorine byproducts in aquatic life.

The UV Experience And Growth

The effects of UV disinfection occur when the system transfers

electromagnetic energy from a mercury lamp to the genetic material of an

organism, i.e. deoxyribonucleic acid (DNA) and ribonucleic acid (RNA). The

wavelength (nm) to effectively inactivate microorganisms is between 250 to

270 nm with an ideal lamp temperature between 95 and 122 degrees Fahrenheit.

This can be accomplished through low-pressure lamps or medium-pressure lamps

(for large facilities).

In the early 1900s, UV disinfection was dismissed in favor of chlorine use

because of the high operational cost and maintenance problems. However, in

recent years UV systems have become cheaper due to technological

advancements. The EPA states the total cost of UV disinfection — including

power consumption, supplies, and miscellaneous equipment repairs — can be

competitive with chlorination when the dechlorination step is included.

In light of these technological advances, UV has been rising in popularity

and is clawing its way to challenge chlorination. In a September 2013

article on the growth of UV, market analyst Frost & Sullivan project the

global demand for UV systems will raise the market to an expected $2.96

billion. This spike is over several industrial sectors with a dependence on

clean water, including medical, power, and food and beverage. In the same

article, the author quotes a manufacturer as noting that North America is

experiencing about 5-percent growth in the UV disinfection market.

There are non-financial benefits that also account for the growth of UV

disinfection, such as disinfection without adding chemicals, no new

creations of toxic chemicals such as trihalomethanes (THMs), and no change

in taste or odor. Furthermore, there is no RMP needed for facilities that

use UV, because there is no regulated chemical in the process. UV systems

can easily be retrofitted to existing chlorine contact chambers (CCC).

However, the gas chlorine facility must de-register the RMP through the

federal EPA system.

![]() IUVA News: Ultraviolet Germicidal Irradiation in Building Air-Handling Systems: State-of-the-Art

IUVA News: Ultraviolet Germicidal Irradiation in Building Air-Handling Systems: State-of-the-Art

Germicidal UV fixtures downstream of a cooling coil

The most recent issue of IUVA News, published by the International

Ultraviolet Association, includes an article from Shelly L. Miller and Julia

Luongo from the University of Colorado Boulder. The article, titled

Ultraviolet Germicidal Irradiation in Building Air-Handling Systems:

State-of-the-Art, discusses the benefits of using germicidal UV in the

air conditioning systems to reduce energy consumption and realize energy

savings. The authors point out that the buildings are responsible for about

40% of the total energy consumption in the USA with more than half of that

going to heating, ventilating and cooling the indoor air.

One of the factors for reduced heat exchange efficiencies and reduced air

flows through heating and cooling equipment is the bio-film forming on the

heat exchangers. The authors cite research according to which various

microorganisms growing inside the air handlers often contribute to

building-related diseases in occupants in addition to increased energy

consumption.

Even though regular cleaning and maintenance of the air handlers is

recommended it is not usually done as often as needed and the chemical

disinfectants used to reduce microbial contamination can be dangerous to the

service technicians as well as the occupants of the buildings. Some harsh

chemicals can also shorten the life of the AC equipment.

The authors assert that there is enough background information and

regulatory requirements to justify the use of germicidal ultraviolet

technology for keeping the air conditioning systems running at design

capacity. This is achieved through reduced bio-fouling and also results in

lower maintenance and energy costs and better indoor environment. The

portion of the GSA Facilities Standards for the Public Buildings specifying

the use of germicidal UV downstream of cooling coils is quoted. It is also

shown that deploying germicidal UV systems for cooling coils can count

toward LEED credits, specifically in the "Innovation by Design" area.

The article concludes that more experimental research is needed in real

buildings as the UVGI technology is increasingly more widely used for energy

and maintenance savings and improvement of the indoor environments.

Germicidal UV should prove to be an excellent tool for achieving energy

savings for many buildings containing heating, ventilation, air conditioning

and refrigeration systems.

Complete article here: Ultraviolet Germicidal Irradiation in Building Air-Handling Systems: State-of-the-Art

![]() Water

Online, Feb 19, 2014:

UV Technology Offers Solution For Emerging Water Crisis

Water

Online, Feb 19, 2014:

UV Technology Offers Solution For Emerging Water Crisis

By Jon McClean

Modern, closed vessel wastewater UV system with

automatic wipers and UV monitor camera.

Picture Courtesy ETS LLC

The emerging crisis of water shortage is now getting more headlines, and

it is noticeable that the political debate now must include measures to cope

with the pending emergency. Across the nation, from northern California to

southern Florida, communities are at risk of simply running out of water. In

January 2014, The California Department of Health produced a list of 17

communities that are within 100 days of running dry. The population of the

U.S. has grown by 99% since 1950, and water demand has surged by 127%. So a

combination of climate change and demand growth is placing unprecedented

demands on potable water, and a recent report by Columbia University cites

water stress in many US cities, including Cleveland, OH, Miami, FL, and

several Texas cities including Houston and El Paso. Several regions now have

in place plans to replace the use of potable water by reclaimed wastewater.

Many are turning to UV as an effective barrier to enable the reuse of

wastewater, for indirect reuse, and aquifer recharge.

UV has been used since 1917, and it is expected that UV will overtake

chlorine as the predominant disinfection method for wastewater within 15

years. UV is a simple, physical and non-intrusive method of rendering

organisms non -viable, and thus unable to replicate or cause further

nuisance. Many microbes now demonstrate tolerance to chlorine; this should

come as little surprise when one considers how mosquitoes have overcome

insecticides, how weeds overcome herbicides, or indeed how microbes easily

overcome antibiotics. UV light works by blowing apart the DNA, found within

all living organisms. When the UV becomes damaged, the normal cell function

of respiration, replication and reproduction rapidly cease. It has been

noted on a number of occasions that when the microbes are exposed to

sunlight, that some repair is observed. This phenomena has led to the older

open channel style UV systems being covered, and indeed has promoted the use

of closed vessel UV systems that keep the sunlight away and the waste

streams completely away from plant operators.

Importance Of Innovation

UV system design has benefitted tremendously from the use of Computational

Fluid Dynamic (CFD) models in the last decade. These models allow system

manufacturers to understand fully the performance aspects of their

equipment, and critically allow the regulatory community to actually

understand the impact of ancillary equipment such as butterfly valves, or

directional elbows have on the performance of the UV system.

As UV became a standard barrier for the drinking water community, the same

rigors is now being applied to UV use for wastewater, or reclaim water.

Once the CFD model has been developed, the model is iteratively refined to

improve the accuracy when compared to the actual microbial performance of

the UV system. Typically the leading UV manufacturers are now able to make

extremely accurate predictions. The wastewater systems are validated,

usually by an expert third party such as Carollo Engineers, or HDR HydroQual.

The performance envelope for the validation experiment is given much

consideration as a typical NWRI (Title 22) system validation can cost well

over $ 200,000 per reactor. The largest lamps currently in use in closed

vessels are 800watt amalgam lamps. The older medium pressure systems that

first appeared for reuse applications are too inefficient, as areas where

water reuse is needed it is typically hot and air conditioner units are very

popular. This makes water reuse areas not just water stressed, but also

power stressed. Many water reuse communities will need to ration power in

the hottest months of the year. Amalgam technology will consume

approximately 1/3 of the power of a medium pressure unit, so communities who

were early adopters are now able to upgrade their older UV systems and see

rapid payback due to energy savings.

In the face of unprecedented climate change, and surging water demand we

have no alternative other than to examine ways of conserving water. Many

traditional uses of water, such as agricultural use, urban irrigation, dust

control, enhanced oil recovery (hydraulic fracturing) will all switch, or

have already switched from using potable water to using reclaimed water. In

many inland communities, the scarcity of available water is leading to the

direct reuse of water. The challenge quickly becomes one of communication

and ensuring that complex, and emotive issues that pose the professional

water community little issue are well explained to a non- technical

customer. In reality we have no choice, but let us take the time to explain

carefully how well protected we really are, and that we do have an

optimistic outlook after all.

![]() IUVA

October 24,

2013 - PR: International Ultraviolet Association (IUVA) Members Present

Awards to UV Innovators at World Congress 2013

IUVA

October 24,

2013 - PR: International Ultraviolet Association (IUVA) Members Present

Awards to UV Innovators at World Congress 2013

World Ultraviolet Congress - September 2013

The International Ultraviolet Association (IUVA) recently held a World

Congress with the International Ozone Association in Las Vegas, NV. During

the conference, the IUVA made some distinguished awards to UV scientists,

engineers, industry leaders and students.

Washington, DC, October 24, 2013 - Members of the IUVA proudly presented

awards to UV scientists, engineers, industry leaders and students at the

World Congress 2013 in Las Vegas.

The UV Engineering Project Award winner for 2011-2012 is the

Catskill-Delaware Ultraviolet Disinfection Facility. The new

state-of-the-art facility is owned by the New York City Department of

Environmental Protection and was designed by CDM Smith and Hazen and Sawyer,

with construction management by Malcolm Pirnie/ ARCADIS and CH2M Hill. The

Catskill-Delaware Ultraviolet Disinfection Facility was recognized as an

exemplary field application of UV Technology.

The Green Innovations in UV Science and Engineering Award winner is a solar powered UV Water Purifier designed by Naiade, for Nedap Light Controls. The IUVA Green Innovations award recognizes an exemplary product or process improving the Green image of UV applications and is reviewed for its Green design and engineering attributes.

The UV technologies industry has grown over the past decade across the globe and is poised for even more expansion with the introduction of UV LED technology. UV LEDs are small, energy efficient devices that have revolutionized the UV industry. The UV Product Innovation award recognizes novel UV product design and engineering. It was given to UV-Pearl for a UVC LED Water Disinfection Device by Aquionics, Inc.

The UV Research Paper of the Year (2011-2012) was awarded to Olya Keen, Nancy G. Love and Karl G. Linden for, “The role of effluent nitrate in trace organic chemical oxidation during UV disinfection” published in Water Research in 2012. A Classic UV Paper Award went to Jeannie L. Darby, Kile Snider and George Tchobanoglous for “Ultraviolet Disinfection of Wastewater Reclamation and Reuse Subject to Restrictive Standards” published in Water Environment Research, 1993.

The UV Light Award for Volunteer Recognition was given to George Elliot Whitby to recognize his dedicated support of IUVA and its mission. The Lifetime Achievement Award in UV Science and Engineering was given to Dr. James R. Bolton, Professor Emeritus of University of Western Ontario and President of Bolton Photosciences Inc.

Students studying UV technology were also recognized for their contributions to research. Best UV Papers were awarded to: Jacque-Ann Grant, University of Toronto; Olya Keen, University of Colorado; Mengkai Li, Chinese Academy of Sciences.

IUVA’s mission is to advance the science, engineering and applications of ultraviolet technologies to enhance the quality of human life and to protect the environment. Founded in 1999, it is a 501(c)3 educational association of more than 500 members in 35 countries. IUVA is recognized as the leading knowledge-base and voice for UV technologies through its varied conferences and programs.

![]() July 11,

2013:

International Ultraviolet Association 2013 World Congress

July 11,

2013:

International Ultraviolet Association 2013 World Congress

IUVA.org

The International Ozone Association and International Ultraviolet Association 2013 Joint World Congress and Exhibition continues a long series of successful congresses organized worldwide by the IOA and IUVA to provide an international forum for all concerned with fundamental, engineering and applied aspects oxidation techniques involving ozone and related oxidants and/or UV techniques.

It will be the third joint IOA and IUVA World Congress and Exhibition that will combine the 20th International Ozone Association World Congress and 6th International Ultraviolet Association World Congress.

![]() June 6,

2013:

Improved Principals of the Biological Safety Cabinet Design

June 6,

2013:

Improved Principals of the Biological Safety Cabinet Design

Labmate-online.com/news/

Improved Biological Safety Cabinet with Germicidal UV

The new CellGard HD ES NU-481 Laminar Flow Class II, Type A2, Biological Safety Cabinet offers personnel, product and environmental protection for handling of hazardous particulate drugs and powders. ISO Class 5 sterility and protection for your valuable in process work materials.

True Laminar airflow provides a sterile environment that minimizes cross contamination. A strong air barrier 105fpm (0.53 m/s) protects the end user from hazardous materials in the work zone. Multiple oval HEPA pre-filters provide the primary means for particulate filtration that allows for an efficient and safe bag-in/bag-out filter change without exposing the interior HEPA filters. Environmental protection is achieved by all contaminated air passing through a 99.99% HEPA filter.

NuAire incorporates our existing technology and new DC ECM technology to give you the best value. There are many added benefits from DC ECM Technology: Less energy to operate, longer filter life, greater horsepower and lower potential RPM; integrated digital control system and the lowest possible noise and vibration.

The unique TouchLink™ Electronic Control System monitors and controls all cabinet functions: On/off functions for fluorescent and germicidal ultraviolet lights, blower motor and interior outlets. Monitors high/low limits for airflow and window position; Date/clock display; laboratory timer, set purge cycles, outlet timer, UV light timer, auto-run timer, night setback, or weekend turn-off; Complete diagnostic functions for a NSF trained service technician or certifier.

![]() June 6,

2013:

Determining Power Quality and Reliability Criteria for Ultraviolet (UV)

Disinfection in Drinking Water Facilities

June 6,

2013:

Determining Power Quality and Reliability Criteria for Ultraviolet (UV)

Disinfection in Drinking Water Facilities

Waterworld.com

There are many benefits in using Ultraviolet (UV) light instead of, or to augment, chlorine disinfection in many drinking water facilities. However, UV treatment presents some unique power challenges not faced by other processes in drinking water treatment. This white paper focuses on the power concerns of UV applications. Because of this power focus, including clarification of the UV Disinfection Guidance Manual, this document is primarily intended for the design of the electrical system feeding UV applications. Some material has been added throughout this white paper and its appendices for facility management and operations personnel.

![]() June 4,

2013: Moldy strawberries? Not for 9 days with UV LEDs

June 4,

2013: Moldy strawberries? Not for 9 days with UV LEDs

John Roach, NBC News

Strawberries are a treat to treasure, but if stashed in the fridge for a

handful of days, they're likely to grow an undesirable goatee of mold. Those

days may be numbered, according to researchers who've shown that exposing

the red fruit to low levels of ultraviolet light doubles their shelf life.

The proof-of-concept results stem from a challenge given by an undisclosed

refrigerator manufacturer to the maker of new light-emitting diodes (LEDs)

that emit ultraviolet (UV) light at wavelengths found in sunlight

transmitted through the atmosphere.

What exactly the lights are doing to the berries to stave off mold is

unknown, according to Steven Britz, a researcher at the U.S. Department of

Agriculture's Food Components and Health Laboratory, who led the experiments

as a side project with funding from the LED maker, Sensor Electronic

Technology Inc.

"We have a hypothesis that we have tested," he told NBC News. "We could be

activating defense genes in the strawberry in part. That's been shown by

other people in published papers."

Other possibilities include a germicidal effect on the mold spores or a

modification of the cell walls on the strawberries that somehow make them

less hospitable to the growth of mold.

Whatever the reason, tests in Britz's lab found that when the strawberries

are stored in a fridge under the lights continuously, spoilage was delayed

for at least nine days, which is more than 50 percent longer than they

unexposed berries.

Analysis of the strawberries revealed slightly higher levels of the red

pigment in strawberries, normal levels of sugars and acidity, he noted.

"The strawberries, from what we could deduce, looked good," Britz said.

But did the researchers eat them?

"No, we didn’t' have enough," he said, explaining that the experimental

setup allowed for just four strawberries in each container, which they kept

for other analytical tests. "But they looked good, and they smelled good … I

wouldn't have hesitated to eat them."

Britz will present the results of the tests at the Conference on Lasers and

Electro-Optics 2013 being held June 9-14 in San Jose, Calif.

![]() March 26,

2013: Crystal IS claims record performance from UV-C LEDs

March 26,

2013: Crystal IS claims record performance from UV-C LEDs

ledsmagazine.com by Tm Whitaker, a Contributing Editor at LEDs

Magazine

Short-wavelength UV LEDs with higher output are likely to be used

increasingly in applications such as disinfecting water, sterilizing

surfaces, and spectroscopy.

Crystal IS, Inc., a manufacturer of ultraviolet LEDs for monitoring,

purification, and disinfection applications, has reported a UV-C LED with an

optical output of 65mW at 260 nm when operated in continuous mode.

UV-C refers to ultraviolet light with wavelengths of 200-280 nm. Light in

the UV-C wavelength range can be used for disinfecting water, sterilizing

surfaces, destroying harmful micro-organisms in food products and in air,

and for spectroscopy applications.

Leo Schowalter, founder and CTO of Cystal IS, described the latest results

as “a technological milestone in the continued development of brighter, more

efficient and reliable UV-C LEDs. By employing die thinning and

encapsulation techniques, we were able to increase the photon extraction

efficiency to over 15%,” he said.

Details were recently published in Applied Physics Express. “By fabricating

our LEDs on our home-grown aluminum nitride (AlN) substrates, we continue to

set the pace of what is possible for the combination of highest efficiencies

and longest lifetimes in the 250-280 nm wavelength range, far surpassing

diodes fabricated on sapphire,” added Schowalter.

Yole Développement estimates that the UV-C lamp market was nearly $200

million in 2012, with lamps being replaced increasingly by UV LEDs.

"Our products will address some of the most pressing health concerns of our

time,” said Therese Jordan, senior VP of business development. “We are

seeing demand in both water and air for the disinfection and

quality-monitoring aspects of UV-C. Similarly, spectroscopic instruments are

also taking advantage of the high light output available in a UV-C LED.

“Unlike UV lamps, UV-C LEDs are mercury-free, compact, rugged and robust,

lending themselves to an array of designs. They hold the promise of long

life and environmentally friendly end-of-life disposal.”

![]() March 19,

2013:

Portland Water District installs ultraviolet micro-organism killer

March 19,

2013:

Portland Water District installs ultraviolet micro-organism killer

therepublic.com

The Portland area's drinking is now safer.

Portland Water District officials on Monday announced that a 5.5-ton

ultraviolet disinfection unit has been installed in an unused underground

well at the district's Standish facility.

It is part of a $12.8 million project designed to eliminate pathogens from

the public drinking water supply.

The 14-foot long unit contains 84 ultraviolet lamps and can treat 52 million

gallons of water a day. The light penetrates micro-organisms and kills them.

A second backup UV unit will be installed later this year.

District spokeswoman Michelle Clements tells The Portland Press Herald the

impact for rate payers is expected to be "minimal."

![]() March 19,

2013:

Study Shows Effectiveness of Ultraviolet Light in Hospital Infection Control

March 19,

2013:

Study Shows Effectiveness of Ultraviolet Light in Hospital Infection Control

infectioncontroltoday.com

Research presented at IDWeek 2012 showed that a specific spectrum of

ultraviolet light killed certain drug-resistant bacteria on the door

handles, bedside tables and other surfaces of hospital rooms, suggesting a

possible future weapon in the battle to reduce hospital-associated

infections.

Researchers at Duke University Medical Center and the University of North

Carolina Hospital System used short-wave ultraviolet radiation (UV-C) to

nearly eliminate Acinetobacter, Clostridium difficile or vancomycin-resistant

enterococci (VRE) in more than 50 patient rooms at the two medical

facilities.

“We’re learning more and more about how much the hospital environment

contributes to the spread of these organisms,” says lead researcher Deverick

J. Anderson, MD, an assistant professor of medicine at Duke and co-director

of the Duke Infection Control Outreach Network. Given previous findings by

the University of North Carolina team that UV-C is effective at decreasing

methicillin-resistant Staphylococcus aureus(MRSA) in hospital rooms, he

believes that the new study lays critical groundwork.

“We have a solid foundation to show that this approach succeeds in both

experimental and real-world conditions,” Anderson adds. “Now it’s time to

see if we can demonstrate that it indeed decreases the rate of infections

among patients.”

His group’s work is among the significant research being discussed at the

inaugural IDWeek meeting, which was held Oct. 17-21 in San Diego. With the

theme Advancing Science, Improving Care, IDWeek features the latest science

and bench-to-bedside approaches in prevention, diagnosis, treatment, and

epidemiology of infectious diseases, including HIV, across the lifespan.

More than 1,500 abstracts from scientists in this country and

internationally will be highlighted over the conference’s five days.

“Healthcare-associated infections are linked with significant morbidity and

mortality,” says Liise-anne Pirofski, MD, an IDWeek chair for the Infectious

Diseases Society of America. “Although there are multiple sources for these

infections, the hospital environment itself can play an important role. The

findings of this study suggest that UV light could hold promise for

eliminating bacteria from hospital rooms and reducing the risk of infection

with these difficult bacterial pathogens in the healthcare environment. That

would be a result to benefit us all.”

UV-C, which is harmful to microorganisms, has been used for decades in food,

air and water purification and to sterilize equipment in laboratory

settings. This study demonstrates that its medical application may offer new

strategies for reducing the estimated 1.7 million hospital-associated

infections that occur annually in the United States. The cost of treating

these infections, often involving increasingly antibiotic-resistant

bacteria, ranges from an estimated $4.5 billion to as much as $11 billion.

In their study, the Duke and University of North Carolina researchers

questioned whether UV-C could be utilized to eliminate three of the most

problematic germs and improve the cleanliness of patient rooms. Given the

tough economics of healthcare today, hospitals’ environmental services are

under pressure to turn rooms over quickly, and many surfaces can get missed

by even the most diligent crews.

The study focused on general-medical and intensive-care units of the two

medical centers and identified patients with infections from the targeted

bacteria. Clostridium difficile, or C. diff as it is commonly known, can

trigger serious intestinal conditions. Acinetobacter can cause pneumonia and

serious blood, wound and urinary tract infections. VRE most frequently

infects the urinary tract, bloodstream, wounds or catheter sites. Each

bacterium can survive for prolonged periods on surfaces.

After the patients were discharged, the researchers obtained multiple

cultures from each of five specific locations in the hospital rooms and

bathrooms – high-touch areas that included bed rails, remote controls and

toilets. A special machine with eight UV bulbs mounted on a central column

was then positioned strategically in each room and turned on for as long as

45 minutes to eradicate both vegetative bacteria and bacterial spores.

Fifteen more cultures were taken from the same locations in every room, and

the pre- and post-treatment bacteria counts were compared.

The numbers of bacterial colony-forming units (CFUs) fell precipitously.

Fifty-two CFUs of Acinetobacter were seen before irradiation, but only 1 CFU

afterward – down 98.1 percent. As for VRE, the proportion decrease was

nearly the same – 719 CFUs before and 15 after, a 97.9 percent drop.

The culturing initially was not sensitive enough to isolate C. diff, but

improved techniques allowed the researchers to do further testing and the

results in the UV-C treated rooms were just as dramatic.

“We would never propose that UV light be the only form of room cleaning, but

in an era of increasing antibiotic resistance, it could become an important

addition to hospitals’ arsenal,” Anderson says.

![]() February

8, 2013:

Karl Linden, President Elect of International Ultraviolet Association Leads

Research Team That Won Gates Foundation Grant

February

8, 2013:

Karl Linden, President Elect of International Ultraviolet Association Leads

Research Team That Won Gates Foundation Grant

marketwire.com / Source: International Ultraviolet Association

Dr. Karl Linden, Professor of Environmental Engineering at University of

Colorado Boulder, leads a research team that was recently awarded a grant

from the Bill and Melinda Gates Foundation for $780,000 for the Reinvent the

Toilet Challenge (RTTC). The grant challenges scientists and engineers to

design a toilet that uses little or no water, is energy and cost efficient

and converts waste into a useful product. Karl Linden's team proposed a

design idea that utilizes solar energy to convert waste into biochar, a

product that can be used as fertilizer.

Dr. Linden is the President Elect of the International Ultraviolet

Association (IUVA), a position he will assume in July of this year. Many of

the scientists and engineers who are members of the IUVA design and maintain

systems that use ultraviolet light to disinfect water, wastewater and air.

These systems are in use across the United States and globally.

Linden will be leading a team of graduate students and collaborating with

two other University of Colorado professors: Environmental Engineering

Professor R. Scott Summers and Chemical and Biological Engineering Professor

Al Weimer. Josh Kearns, a PhD candidate, has been using a biochar process to

purify drinking water in developing countries. Kearns will provide his

expertise for the RTTC project.

"This project is also very student-driven," said Dr. Linden in a press

release issued by University of Colorado. "Students with classroom and

field-based experiences in our Engineering for Developing Communities

program have provided some excellent ideas, expertise and enthusiasm to make

this project possible."

Paul Swain, President of IUVA, has been a colleague of Linden's for some

time. "Once again, Karl Linden is at the forefront of critical issues

impacting public health and the environment worldwide," says Swain. "The

IUVA is fortunate to have a true leader in our field as our next

International President," he added.

IUVA's mission is to advance the science, engineering and applications of

ultraviolet water disinfection and air pollutant technologies to enhance the

quality of human life and to protect the environment. Founded in 1999, it is

a 501(c)3 educational association of more than 500 members in 35 countries.

IUVA is recognized as the leading knowledge base and voice for UV

technologies through its varied conferences and programs. Visit

IUVA.org.

![]() January 15, 2013: UV Experience for Inactivating Cryptosporidium in Surface Water Plants

January 15, 2013: UV Experience for Inactivating Cryptosporidium in Surface Water Plants

Wateronline.com / Authors: Keith Bircher, G. Elliott Whitby and John Platz

Regulatory Background - The disinfection of pathogenic microbes in drinking water has been successful over the last century largely due to the use of chlorination. However, research conducted in the 1970’s revealed that by-products formed during the chlorination process are potentially carcinogenic and that there is a direct correlation between the concentration of chlorination by-products and the probability of certain cancers and other health problems. Following these discoveries, drinking water regulators have struggled within the confines of technological and economic limitations to find a balance between the benefits of chlorination and its harmful side effects.

In the U.S.A., the Surface Water Treatment Rule (SWTR) of 1989 mandates inactivation levels for Giardia cysts and enteric viruses, and also sets treatment standards for Trihalomethanes (THM’s, a common disinfection by-product). The SWTR provides guidance to drinking water facilities through “CT” tables that prescribe the inactivation efficacy of various processes under varying water quality conditions. By following this guidance, most water treatment plants were able to provide an adequate degree of disinfection while not compromising their Disinfection By-Product (DBP) limits and without requiring major changes to their plants. However, continuing DBP health effect research indicated that even the DBP standards required in the SWTR of 1989 produced an unacceptable level of risk and the SWTR was amended in 1996 to lower the level of DBP’s. The new DBP standards have caused many plants to fall out of compliance, requiring either extensive plant modifications or new disinfection strategies. In addition, a major outbreak of cryptosporidiosis in Milwaukee in 1993, and other minor cryptosporidiosis and giardiasis outbreaks caused regulators to create a removal requirement for Cryptosporidium oocysts in the 1998 Interim Enhanced Surface Water Treatment Rule (IESWTR) and a further treatment requirement in the Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) which was promulgated in December 2005. The LT2ESWTR includes a treatment requirement for Cryptosporidium and many surface water plants will fall out of compliance due to the very poor ability of chlorination to inactivate Cryptosporidium. A void was created for water treatment technologies that will inactivate protozoa and viruses, not create DBPs, and are economically feasible. One technology that meets all three criteria is ultraviolet (UV) disinfection.

Ultraviolet light has long been known to be effective for the inactivation of viruses and bacteria in drinking water and guidelines for the disinfection of viruses with UV light exist in the U.S. EPA Alternative Disinfectants and Oxidants Guidance Manual. However prior to 1998, UV was widely considered to be ineffective at economically feasible UV doses for encysted protozoa (like Giardia and Cryptosporidium), as it was thought that UV would have to rupture the cyst membrane wall. Since Giardia was the controlling microbe for the determination of the dose of chlorine and since the UV dose required for Giardia was believed to be completely too high to be considered, no reductions in chlorine usage could be gained by using UV. As a result, UV disinfection was not used for drinking water in North America; however it has been and continues to be used extensively in Europe for groundwater.

Breakthrough research conducted by Calgon Carbon Corporation in 1997 and 1998 proved that UV disinfection is, in fact, very effective for inactivating Cryptosporidium and Giardia at low UV doses. Subsequent to Calgon Carbon’s research, the U.S. EPA created a UV working group to report to the Federal Advisory Committee (FACA) on issues and costs related to UV disinfection, resulting in the development of the UV Disinfection Guidance Manual (UVDGM) by the U.S. EPA and the promulgation of the LT2ESWTR. Many utilities are now using or are considering UV disinfection in their plants as either an additional barrier for protozoa disinfection or to get disinfection credits for Cryptosporidium and/or Giardia and to lower chlorine doses to meet the 1998 DBP standards.

Read complete article:

UV Experience for Inactivating Cryptosporidium in Surface Water Plants

/PDF/

© 2002 - 2021

American Air & Water®, Inc.

843-306-0070

Privacy Statement and other Policies

uv disinfection | uv systems | uv science facts | press releases | links and q&a | uv programscontact | login