|

Hospital / OR UV Disinfection | |

| Contact | Login | ||

| profile | uv systems | uv science facts | press releases | uv info | business programs |

UV Applications in Hospitals

|

|

|

UVGI Systems for Hospitals & OR

Click on these links for additional information

» Complete UVGI Systems Package for Operating Rooms /PDF/

» OR UV Package Instructions /PDF/

» Medical center bacteria & fungi levels "before and after" UVGI Installation /PDF/

» Ultraviolet Radiation Compared to an Ultra-Clean Air Enclosure /PDF/

» UV Control of Airborne Hospital Infections /PDF/

» Safety of Upper-Room Ultraviolet Germicidal Air Disinfection for Room Occupants /PDF/

» Medical Costs of Hospital Infections in US Hospitals & Benefits of Prevention /PDF/

» UV Report by Dr. Kowalski, PE, PhD - Surgical Site & Nosocomial Infections

»

Ultraviolet Lighting During

Orthopedic Surgery and the Rate of Infection

Utilizing Germicidal UV Technology to Inhibit Microbial Growth and Limit Transfer of Infections in Hospitals

UVC can be utilized to inhibit microbial growth and transfer in hospitals through installation in HVAC systems and stand-alone fixtures as follows:

- Cooling Coil disinfection – installation of UVC fixtures for direct irradiation of the cooling coils

- Air disinfection – installation of in-duct UVC air cleaners for air stream irradiation; additional in-room UVC fixtures can be used for upper air disinfection

- Surface Sterilization with direct UVC fixtures

- UVC for Operating Rooms – a unique combination of air and surface sterilization systems specifically designed for Operating Rooms

- Mobile UVC Room Sterilizers – used in unoccupied rooms where

installation of permanent fixtures is not practical.

- Mobile UV System with 24 UVC lamps ARTZ

- UV Mobile Room Sterilizer with 8 UVC Lamps

- Mobile UV System with 4 High Output UVC Lamps

The primary difference in using UVC in air purification and surface

sterilization is residence time - the amount of time the microorganisms are

exposed to UVC radiation. In moving air streams germs are traveling at high

speeds and therefore may be exposed for only a fraction of a second. Because of

this, it is important to apply more UVC energy with High Output UVC lamps to get

the disinfection desired.

With surface sterilization, there is an almost unlimited residence time

therefore less UVC intensity is necessary. The dose needed for effective

sterilization is a function of UVC intensity, time and distance from the

surface.

Overhead UVGI at St. Francis Hospital

OR UVC sterilization is a specifically developed sterilization solution.

Ensuring a sterile environment is very important for preventing complications

during organ transplantation or open joint surgical procedures. Achieving and

maintaining a sterile environment in operating rooms is crucial for patients

with weak immune systems due to cancer or AIDS. Operating room UVC sterilization

package compiles all implementations of the germicidal UV technology to ensure

the required clean environment.

Operating Room UVC sterilization is achieved with two distinctive, although

overlapping processes. First, before the operating room is occupied by people,

it is entirely irradiated with direct UVC fixtures that sterilize all surfaces

exposed to the UV rays. These fixtures must be turned off or turned down before

personnel or patients enter the operating room. Second, the air of the operating

room is irradiated with indirect germicidal fixtures to ensure sterile

environment and stop the transfer of pathogenic or toxic microorganisms through

air. The indirect fixtures stay on all the time. They either enclose the UV

lamps or are equipped with louvers that direct the UV light to areas above eye

level.

Germicidal UV door barriers are also utilized to prevent the harmful

microorganisms from entering the sterile environment from outside of the

operating room where the level of sterility is not as high.

Complete UV Package for Operating Room

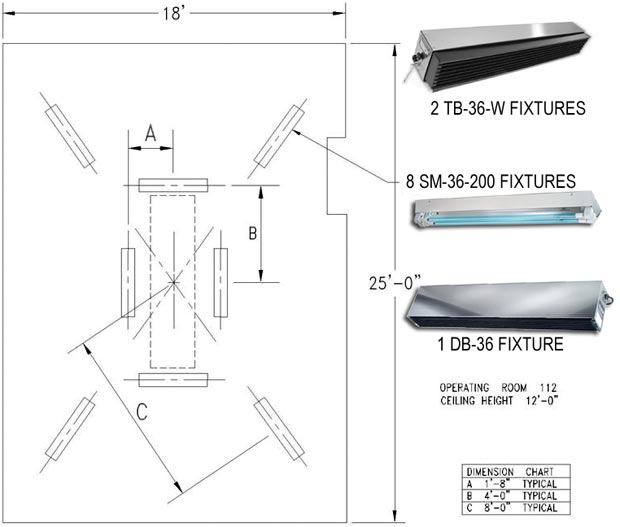

A sample layout of the direct SM-36-200 UV fixtures shown below.

The TB-36-W systems are wall mounted and stay

at full power at all times during procedure for upper air

disinfection. The DB-36 system is installed above the door to create a UV

curtain for air disinfection. The DB systems also stay at full power during

operation procedures. More than one DB UV fixtures may be required depending on

the width of the door. The SM-36-200 are direct germicidal UV systems

installed in various patterns on the ceiling above the operating table. The UV

intensity of these fixtures is controlled by a variable transformer to avoid

over-exposure during surgery.

Click here for complete OR UV

Package description and instructions » /PDF/

Another possible entryway for the airborne microbes could be through the hospital HVAC system. This could be avoided with installation of UVC lights for air and surface sterilization in the hospital HVAC systems.

Direct surface UVC irradiation of the HVAC coils and dripping pans inhibits

development of colony forming microorganisms. Air stream UVC irradiation

sterilizes airborne germs such as bacteria, fungal particles, mold spores, and

viruses.

A proper germicidal UVC light installation in the HVAC system will break the DNA

of the microorganisms that reside in the ducts or circulate in the air-stream.

Therefore as the indoor air circulates throughout the system virtually all

airborne microorganisms will be rendered non-viable. The dead microbes cannot

form new colonies but they still could be spread throughout the building. Since

the dead microorganisms still represent a health hazard, it is strongly

recommended that UVC is used in conjunction with HEPA filters. The HEPA filters

capture particles smaller than one micron, i.e. the non-viable spores and

bacteria would be captured and removed from indoor air. If only a HEPA filter is

used without the UVC light, the filter itself will become a breeding ground for

new colonies.

It has been proven that colony forming microorganisms will not grow or reproduce

if they are directly irradiated with appropriate dosage of germicidal UV. As the

indoor mold colonies grow they produce millions of spores that are blown through

the HVAC ducts and distributed in the indoor environment. Once the spores are

spread inside they just need food and water in order to start growing,

reproducing and forming countless new colonies that release countless new

spores. This is the mechanism of infesting the indoor environment of some

contemporary airtight buildings with mold to such extent that it becomes

impossible for people to live or work there. All this leads to lawsuits, big

expenses for mold cleaning, huge losses and worst of all - health problems for

many people. This could be avoided by installing specially designed germicidal

UV fixtures that shine directly on the coils and drain pans. This is an

effective solution for microbial growth inhibition.

The effectiveness of germicidal UV has been recognized by the U. S. General

Services Administration Office of the Chief Architect and incorporated in the

Facilities Standards for the Public Buildings as follows: "Ultraviolet light (C

band) emitters/lamps shall be incorporated downstream of all cooling coils and

above all drain pans to control airborne and surface microbial growth and

transfer. Applied fixtures/lamps must be specifically manufactured for this

purpose."

Germicidal UV light can be effectively utilized in hospitals and public

buildings to inhibit microbial growth, spreading of infections and to increase

indoor air quality. UVC can also help against mold problems by rendering

airborne mold particles and mold spores non-viable and sterilizing surface mold

colonies.

Main factors for the effectiveness of in-duct UVC systems intended to disinfect

moving airstreams are UVC intensity at operating conditions, microbial

susceptibility to UVC, duct wall reflectance and the cumulative effect of UVC on

the microorganisms.

Given this information, UVC system designers can make educated performance

estimates for the HVAC applications in hospitals. The results will provide

measurable cost savings by:

- Reduction in patient and staff medical expenses resulting from nosocomial infections, operating room infections, and aspergillosis

- Reduction in routine maintenance costs for cleaning of ducts and coils

- Improved efficiency of HVAC systems resulting in energy savings and extended life of the systems

The effect of UVC installed in HVAC systems can be further improved by utilizing of direct UVC lights for air and surface sterilization in waiting rooms, TB wards, operating rooms and laboratories. Portable and mobile UVC devises can be used as well.

© 2002 - 2021

American Air & Water®, Inc.

843-306-0070

Privacy Statement and other Policies

uv disinfection | uv systems | uv science facts | press releases | links and q&a | uv programscontact | login